Key Features

Applications

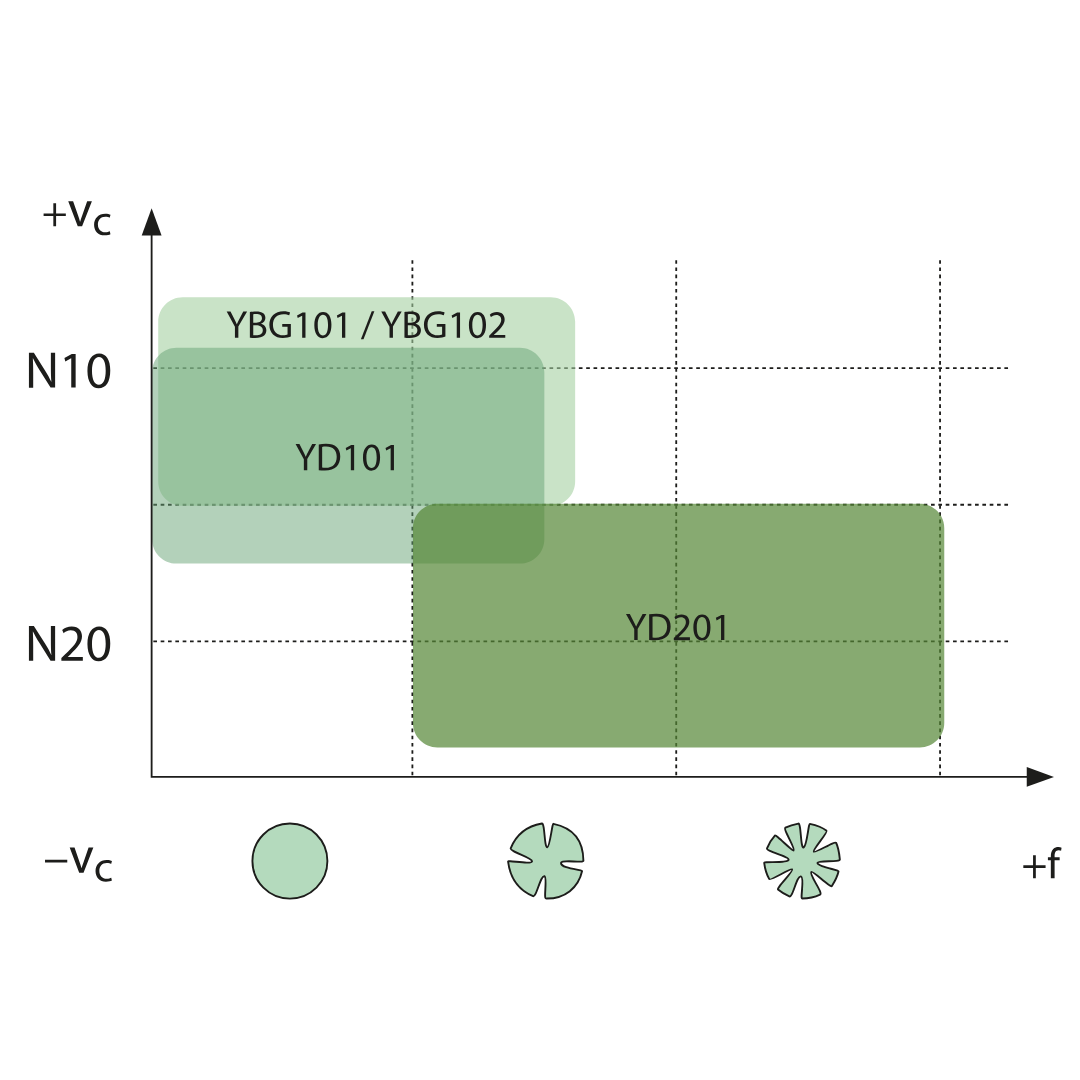

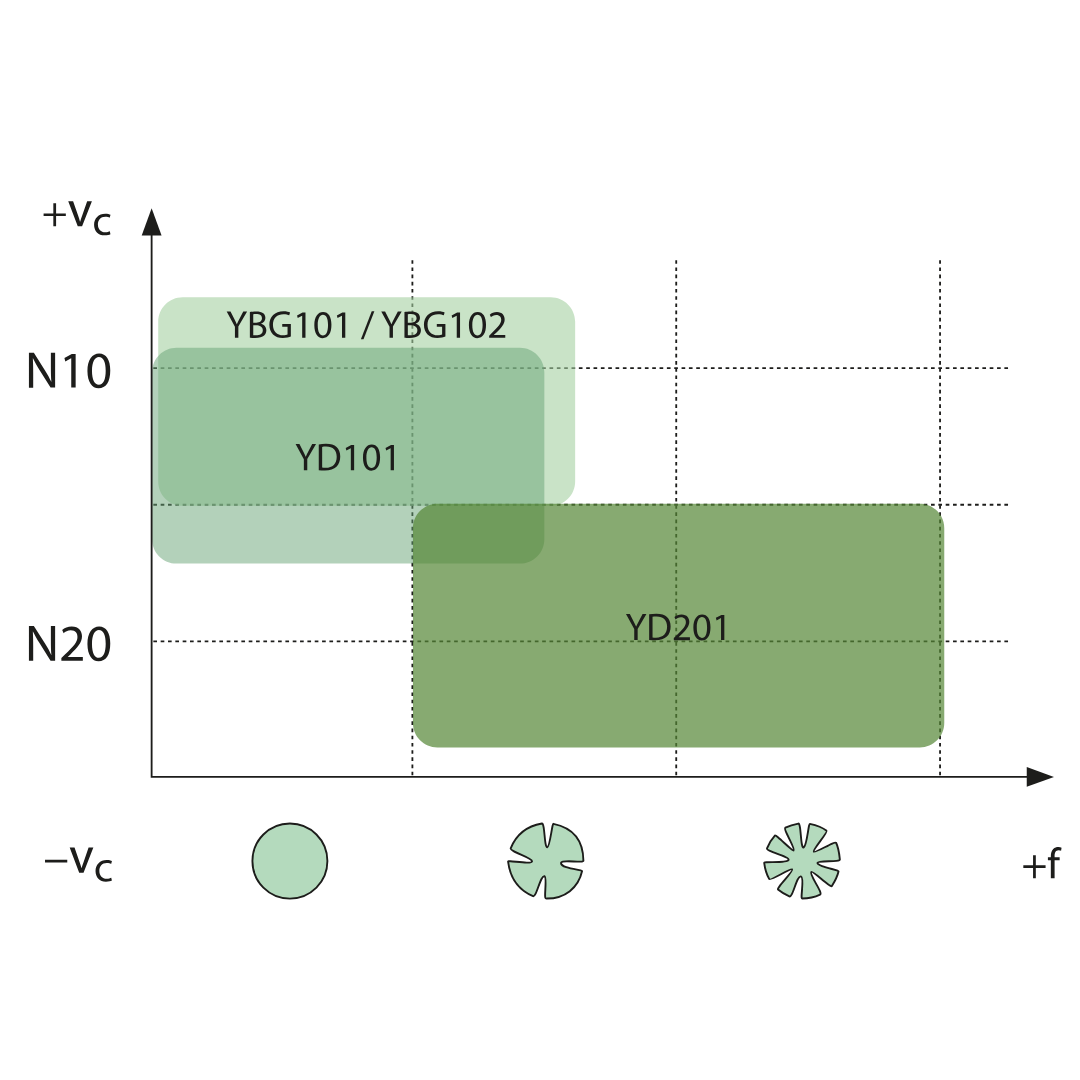

YD201

ISO: K10 — K30, N10 — N30

Uncoated N10–N30/K10–K30 carbide substrate for medium application in aluminium and other material.

YD101

ISO: N05 — N20, K05 — K20

Uncoated N05–N20/K05–K20 carbide substrate for fine to medium application in aluminium and other material.