Threading

Applications

Applications / Threading

Key information on threading

There are a variety of machining strategies used in the metal working industry to produce top-quality components. Threading comes with its own set of challenges.

What is threading, and what are the main factors to consider? Here are the things you need to know to succeed.

A screw thread can be used in many ways, such as a fastening screw thread, a motion screw thread, or a transport thread. Thread cutting, thread drilling, and thread milling are all methods used to create a thread, each with its own special features requiring detailed planning to ensure success.

Thread cutting: The rotating tool generates the cutting motion, with the feed rate corresponding to the thread pitch. Depending on the type of thread, it may be necessary to adjust the number of cutting passes and the cutting depth.

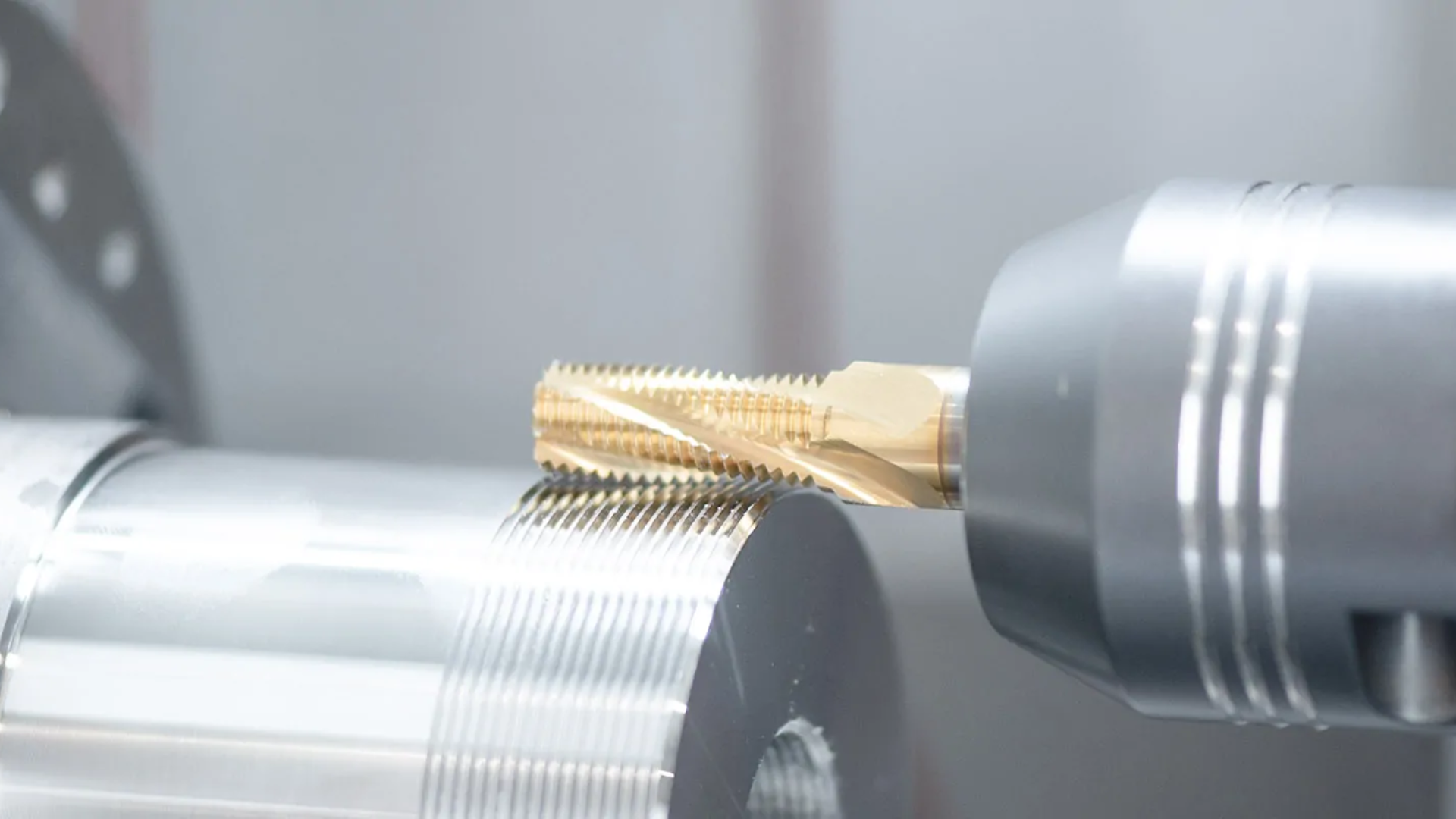

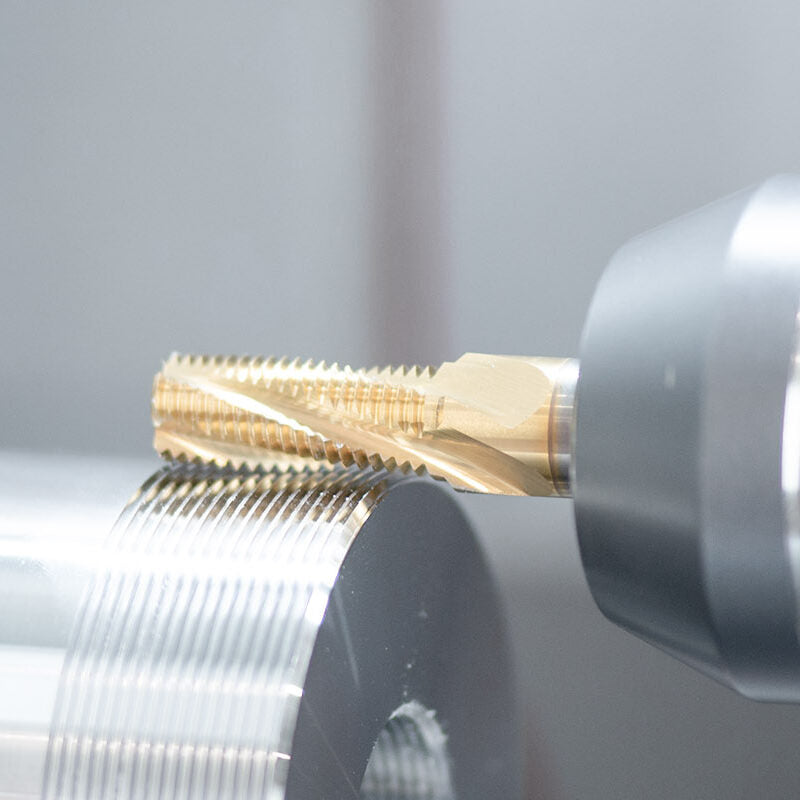

Thread milling: Thread milling on a CNC lathe involves creating threads using a rotating tool and its plunge motion. The thread pitch is determined by the lateral movement of the tool during its rotation.

Is a viable method for creating threads on a CNC lathe, especially for complex, high-precision threads or large-diameter threads. It offers excellent accuracy and flexibility for non-standard or difficult-to-machine threads.

ZCC Cutting Tools Australasia is here to answer any questions you may have. Do you need help with your threading applications? Contact us — we’re here to help.

Recommended Tools

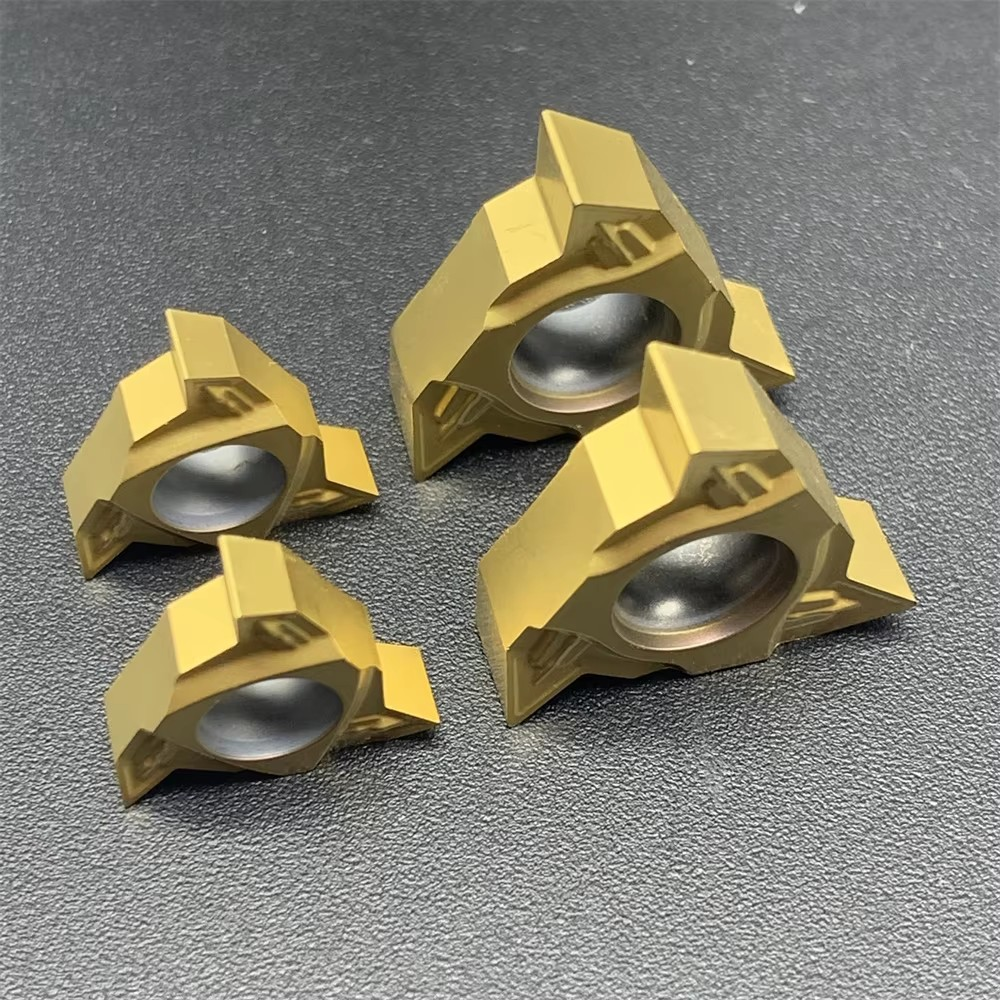

Threading Inserts

Tackle machining challenges with confidence. ZCC Cutting Tools’ high-quality tungsten carbide threading inserts — available in ISO Metric, Whitworth, and Unified standards — deliver reliable chip control, extended tool life, and shorter cycle times. Grades like YBG203 and YBG205 ensure consistent, cost-effective results for your operations.

Threading Holders

Boost your productivity with ZCC Cutting Tools' reliable threading tool holders—engineered for precision and consistent performance in turning, grooving, and parting-off operations. Achieve superior results with every cut.

Thread milling on a CNC Lathe

Thread milling on CNC lathes offers precision and flexibility for complex or large-diameter threads. ZCC Cutting Tools’ solid carbide 4111 series thread end mills — available from M3 to M20 — deliver exceptional results on carbon and alloy steels. Perfect for boosting accuracy and efficiency in your machining.