Hardened Steel

Materials

Materials / Hardened Steel

A Vital Material for Key Industries

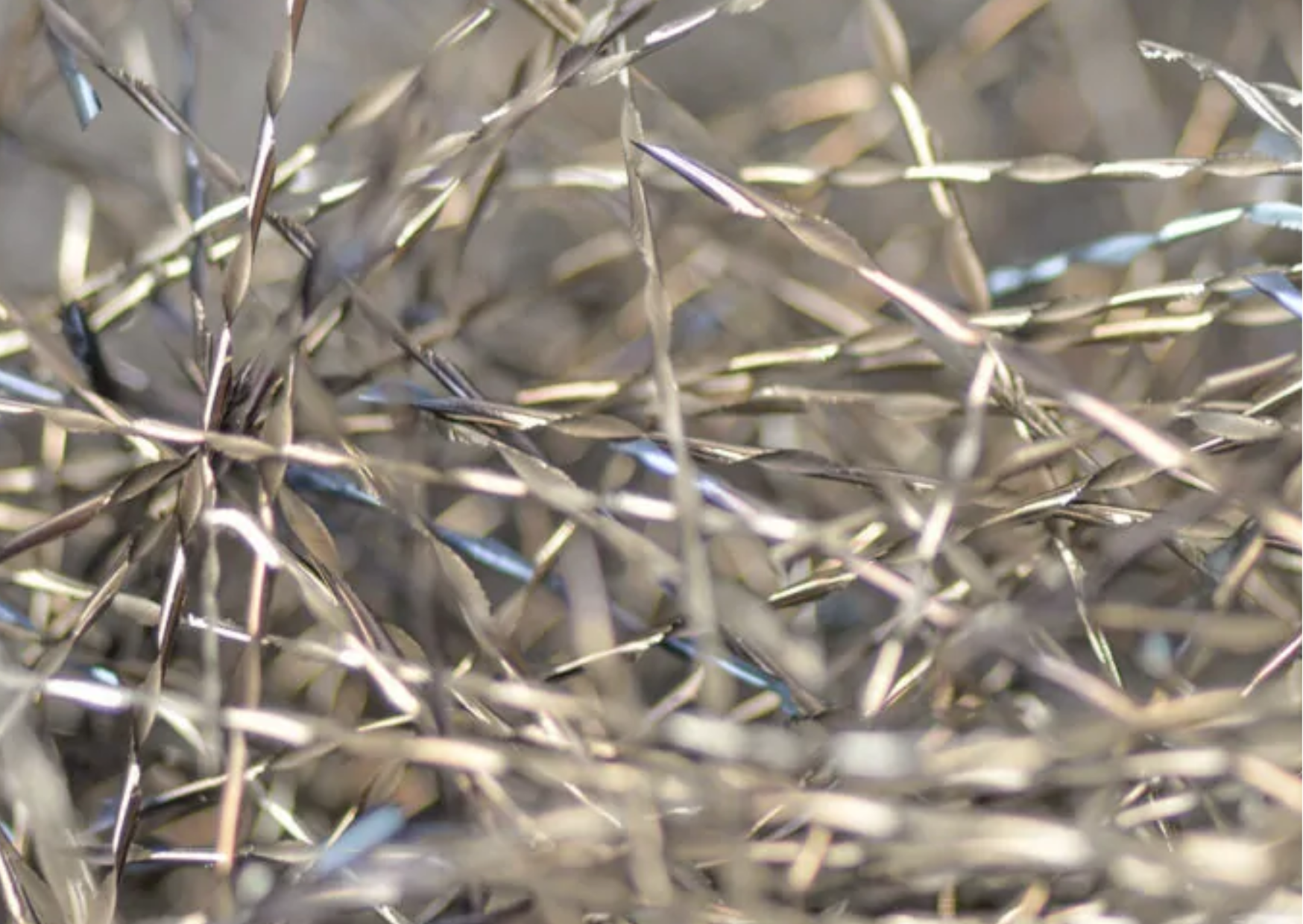

Hardened steel is characterized by a particularly high mechanical resistance and is used in sectors such as the automotive industry and mechanical engineering. One group of materials is the ISO H group. The materials in this group have a hardness of between 55 and 70 HRC, which makes them especially difficult to machine.

Hardened Steel and the Particular Challenges it Poses

Hardening steel is a process designed to enhance its mechanical properties. Various hardening methods exist, with case hardening being particularly important. In case hardening, workpieces are carburized to create a hard edge layer up to 4 mm thick while keeping the core tough. The parts are heated to the tempering temperature and then quenched using water, oil, molten salt, or inert gases.

The following hardened steels are commonly used in the industry and present specific challenges:

- 100Cr6 (DIN 1.3505, ISO 683-17): This steel, with a hardness of 60 HRC, is used in the automotive industry and mechanical engineering, particularly for rolling bearings. It is relatively tough, wear-resistant, and maintains high stability during tempering, rarely deforming during heat treatment. It also has high resistance to contact fatigue. However, machining 100Cr6 can lead to high tool wear and heat stress.

- EN-GJL-200 (DIN GG20, ISO 185): Also known as GG20, this hard-cast iron grade is used for gearing due to its high thermal conductivity, good damping properties, and high rigidity. GG20 wears out cutting tools quickly and achieving target dimensions during machining can be challenging. It is widely used in the automotive industry.

- PM23 (DIN 1.3344 PM, ISO 4957): This high-speed steel is used in mechanical engineering for constructing stamping, cutting, forming, and machining tools. PM23 is very wear-resistant, tough, and dimensionally stable. Proper tools and process parameters are essential for machining PM23 effectively.

Machining hardened steel demands high-quality cutting tools. Whether drilling, turning, or milling, it poses technical challenges. ZCC-CT offers specialized tools for hard machining these materials.