Key Features

Applications

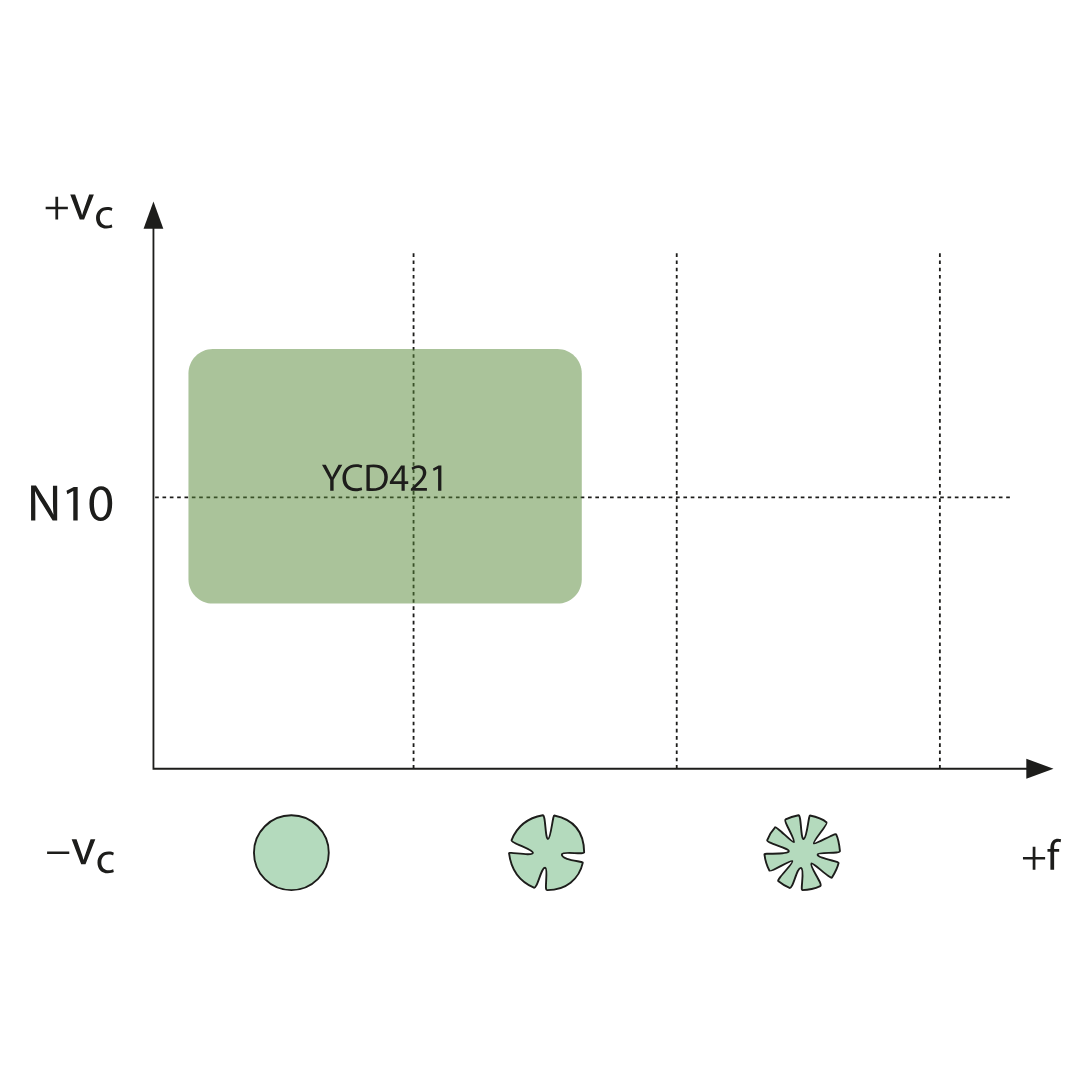

YCD421

ISO: N01 — N10

Uncoated, brazed N01–N10 PCD grade for fine finishing operation of aluminium alloys less than 12% Si, composites, copper/magnesium and other alloys. Medium grain size grade with good wear resistance for a wide application field.