Key Features

Applications

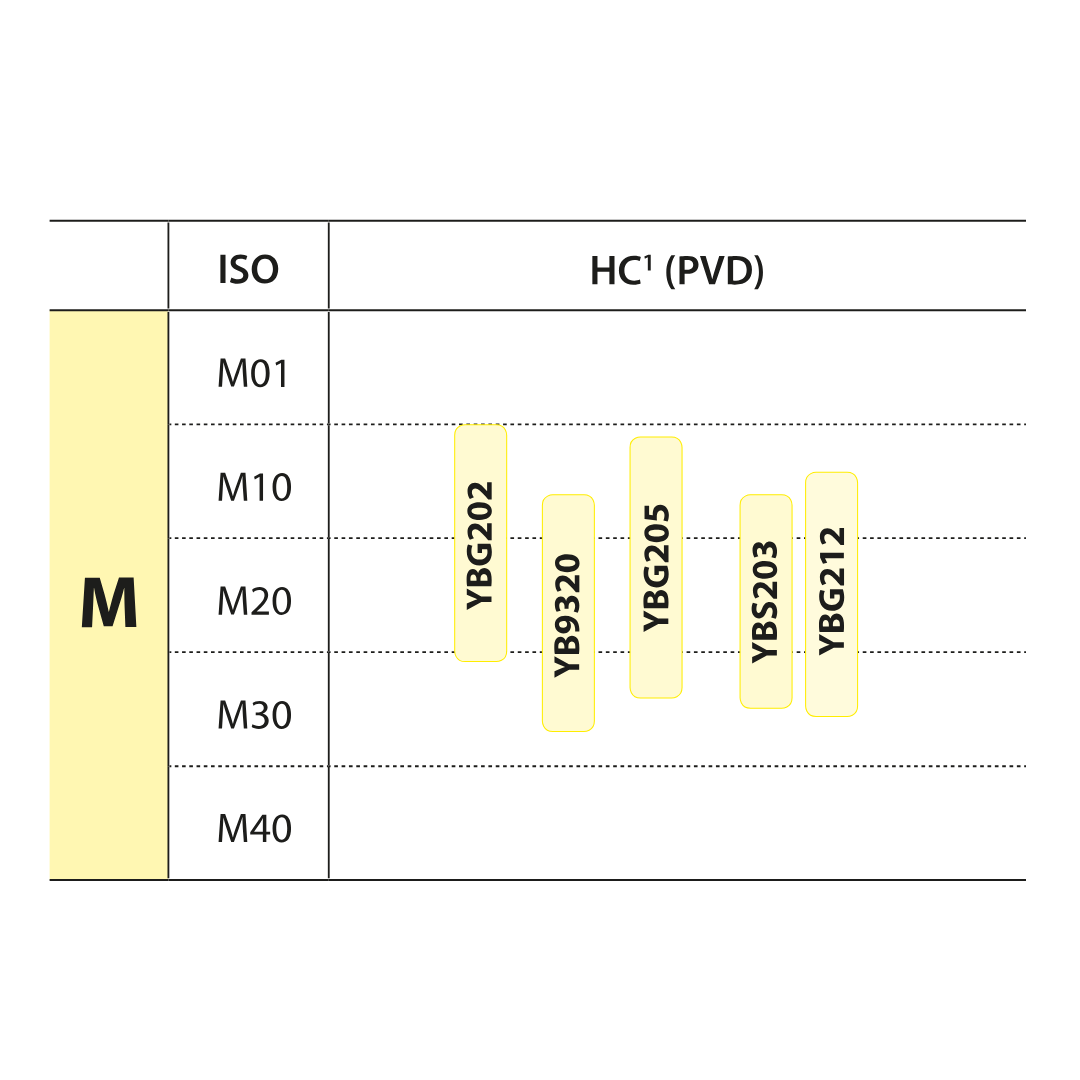

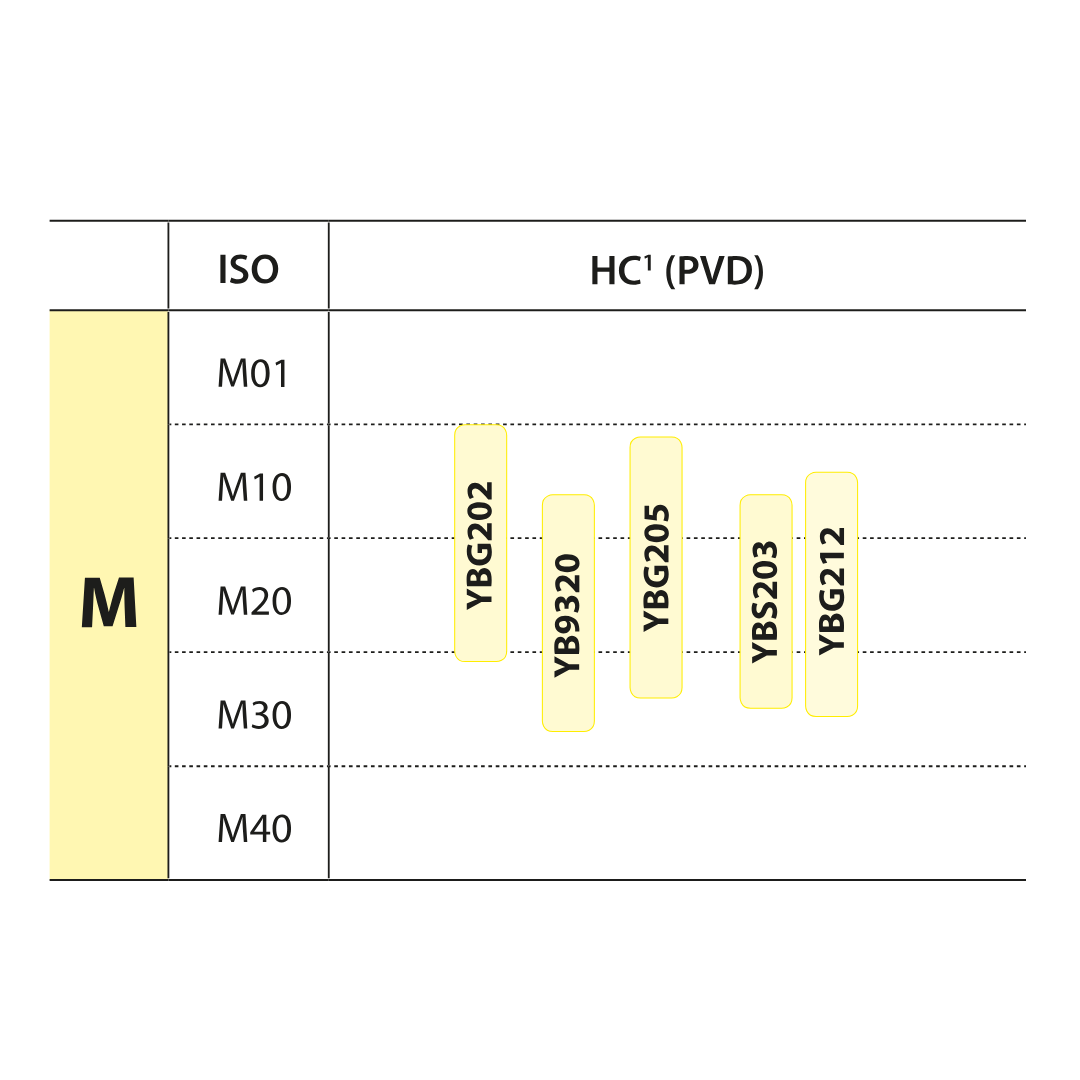

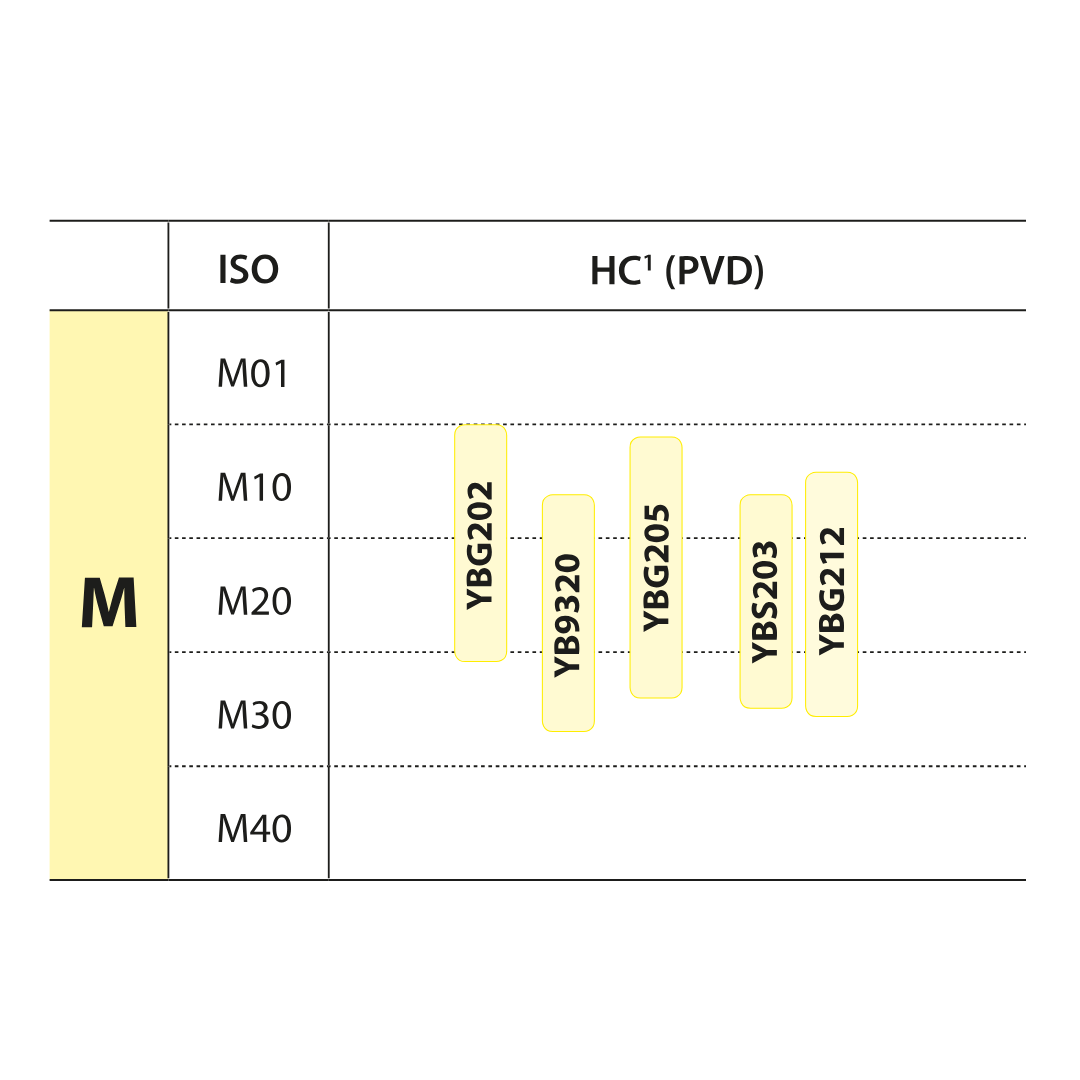

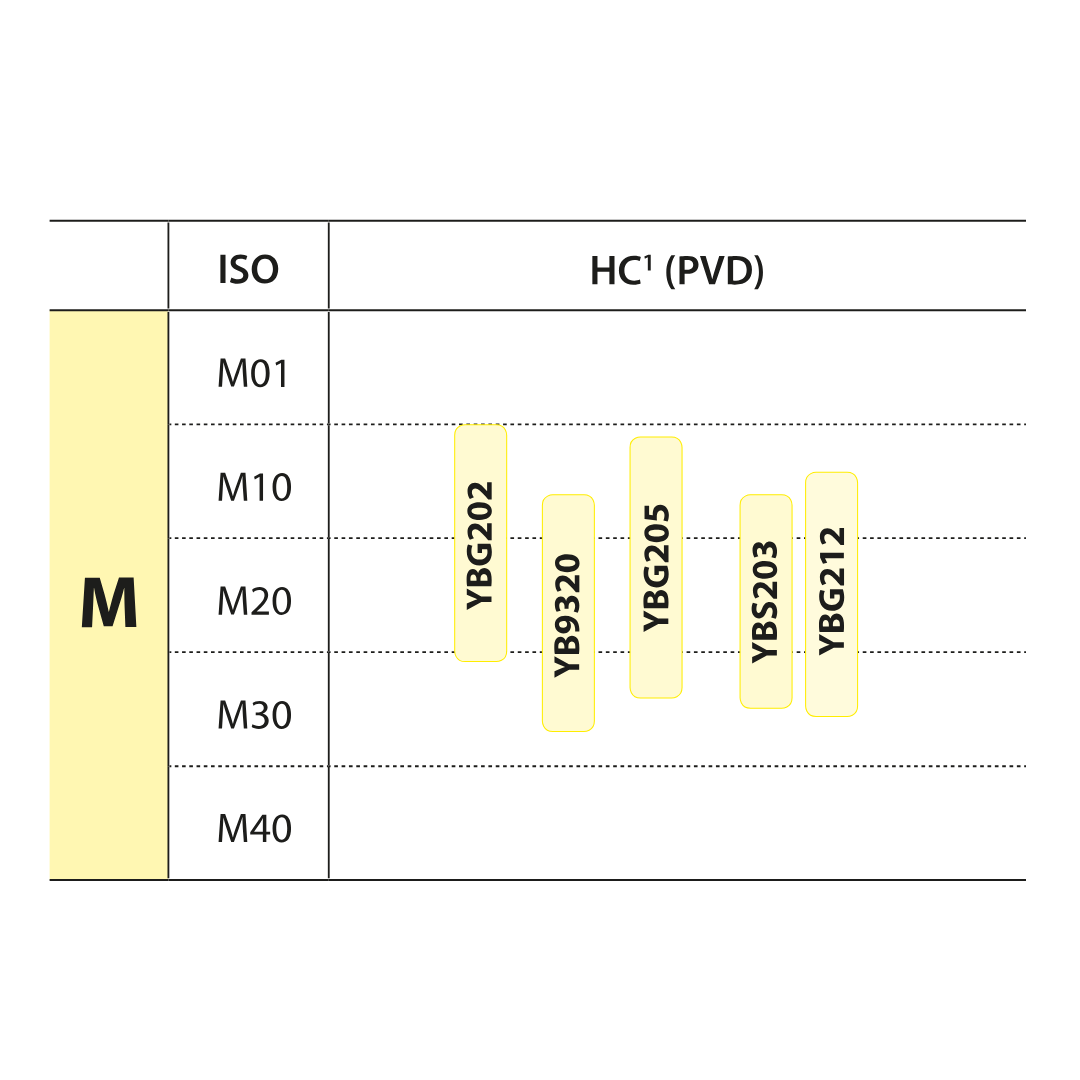

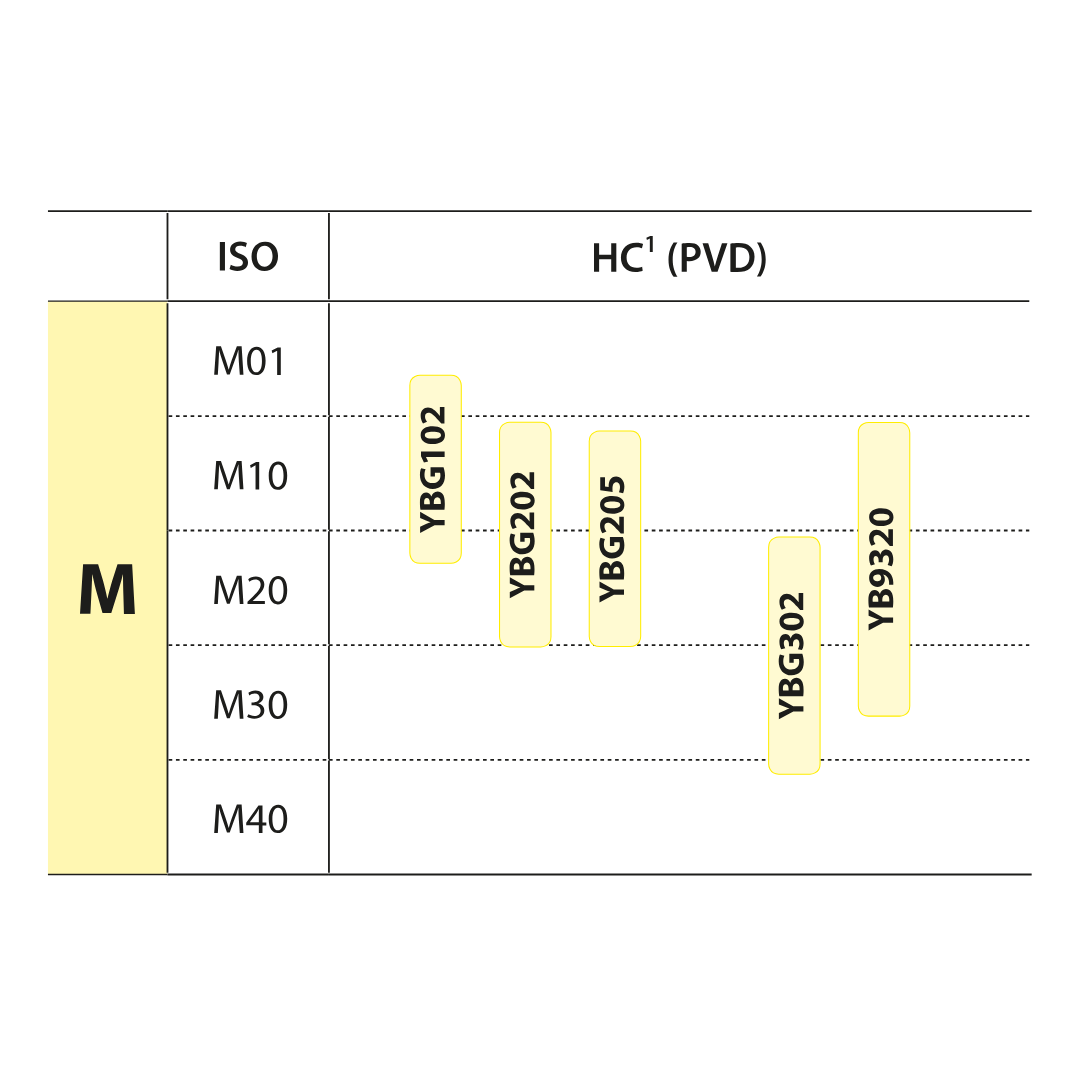

YBG212

ISO: P25 — P35, M25 — M40

PVD coated M25–M40/P25–P35 carbide substrate for steel and stainless steel. Especially for inner insert at drilling operation.

YB9320

ISO: P10 — P30, M10 — M25

PVD multilayer coated M10–M25/P10–P30 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (grooving/milling). Optimized coating stability for higher wear resistance and thermal stability in a wide application field.

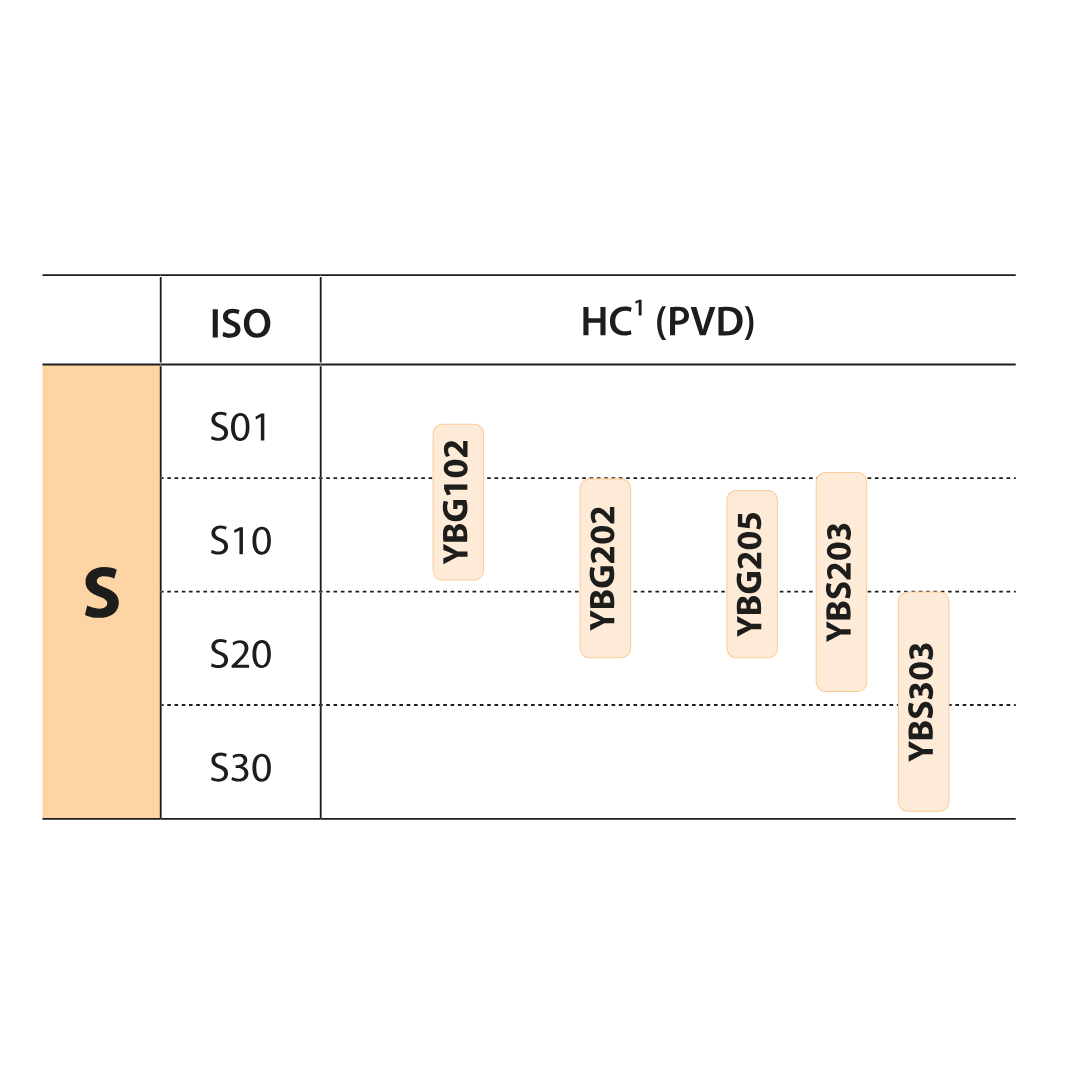

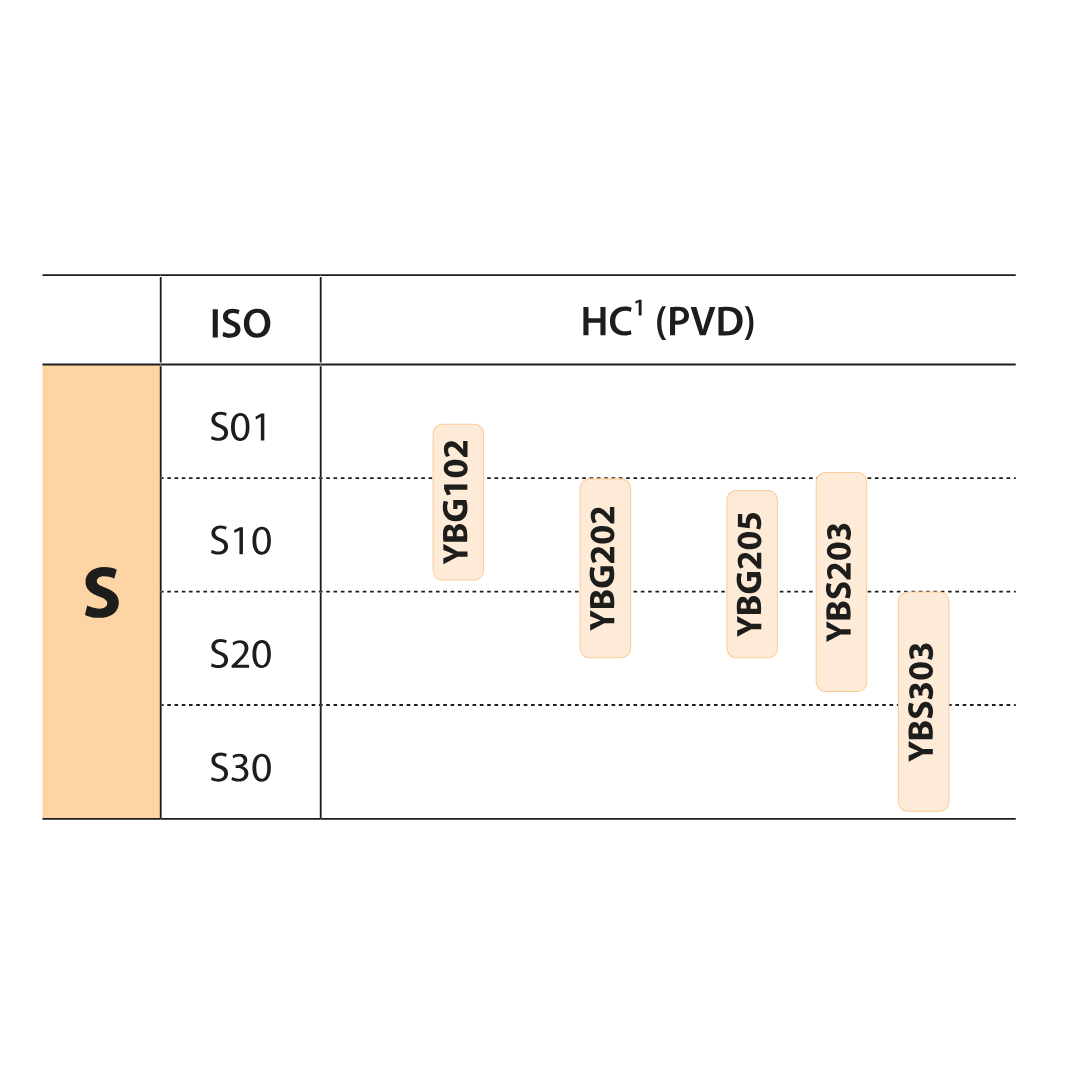

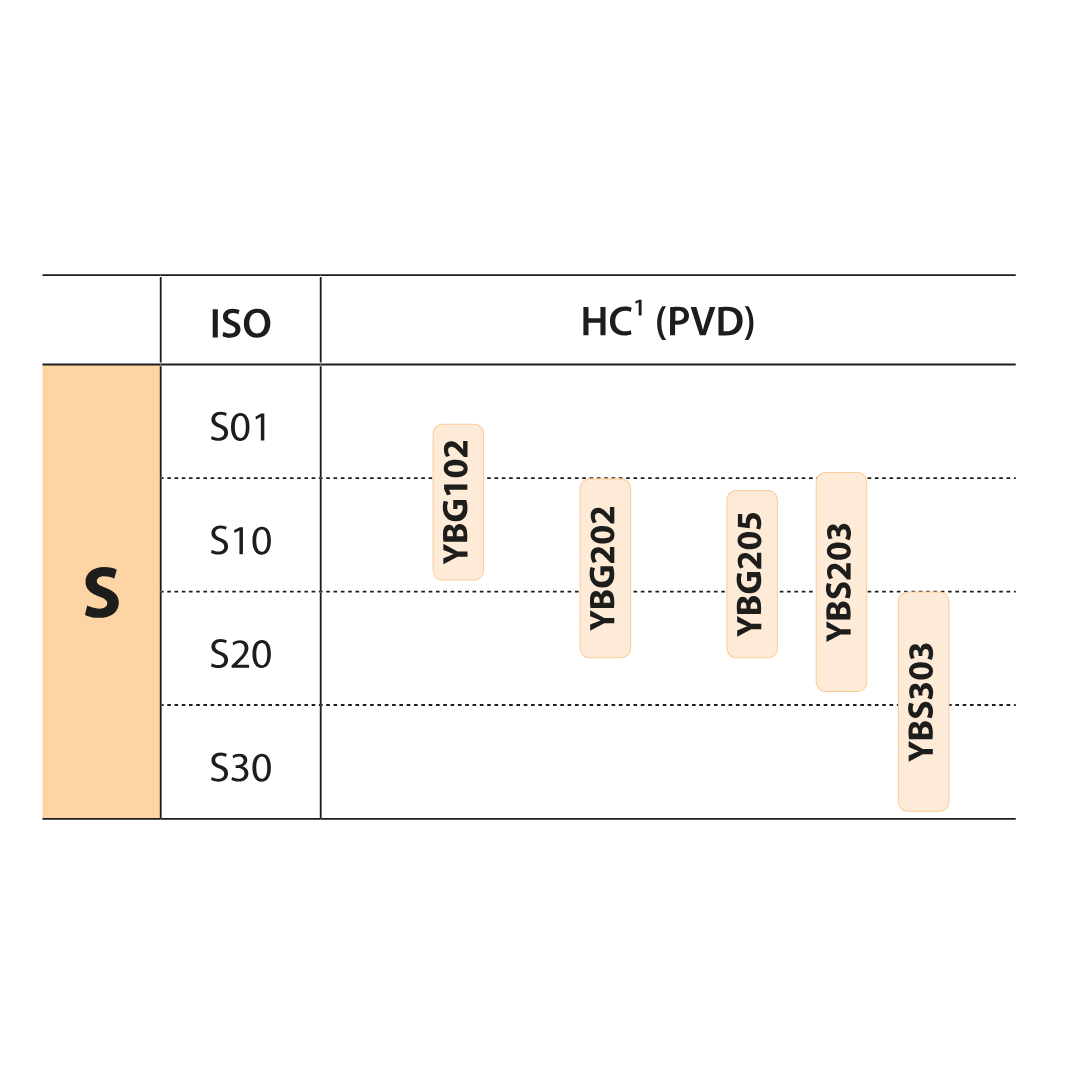

YBG205

ISO: P10 — P30, M20 — M40, S15 — S25

PVD multilayer coated M20–M40/S15–S25/P10–P30 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (milling). Good wear resistance and thermal stability in a wide application field.

YBS203

ISO: S15 — S25

Turning and milling grades for processing heat-resistant materials. A special carbon substrate and the latest PVD coating technology enable a very good wear behaviour, high fracture toughness and high thermal stability.

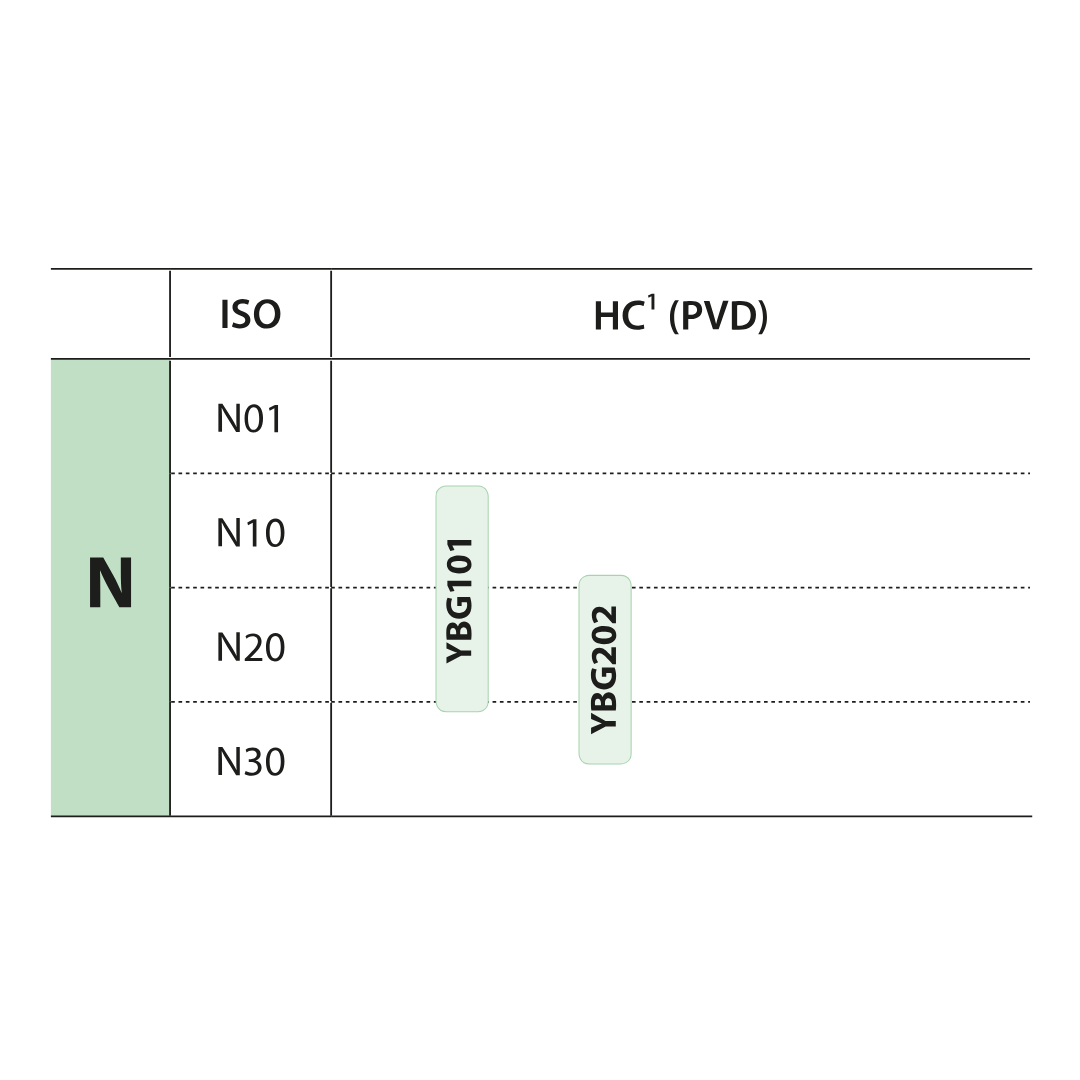

YBG202

ISO: P10 — P30, M10 — M25

PVD coated M10–M25/P10–P30 carbide substrate for finishing to medium application of stainless steel and steel (milling). Good wear resistance in a wide application field.

YBS303

ISO: S25 — S35

Milling grade for machining titanium alloys. A tough carbide substrate and the latest PVD coating technology with increased impact resistance and high thermal stability.

YBG302

ISO: P15 — P30, M25 — M40

PVD coated M25–M40/P15–P30 carbide substrate for medium roughing application of stainless steel and steel (milling). Good wear resistance and toughness.

YBG102

ISO: S05 — S15

PVD coated S05–S15 carbide substrate for finishing to medium application of super alloy material, stainless steel and aluminium. Good wear resistance in a wide application field.

YBG101

ISO: N05 — N20

PVD coated N05–N20 carbide substrate for finishing to medium application in aluminium material. Coating only on the top face, in combination with the aluminium chip breaker, prevents build up edges and gives a smooth cut.