Key Features

Applications

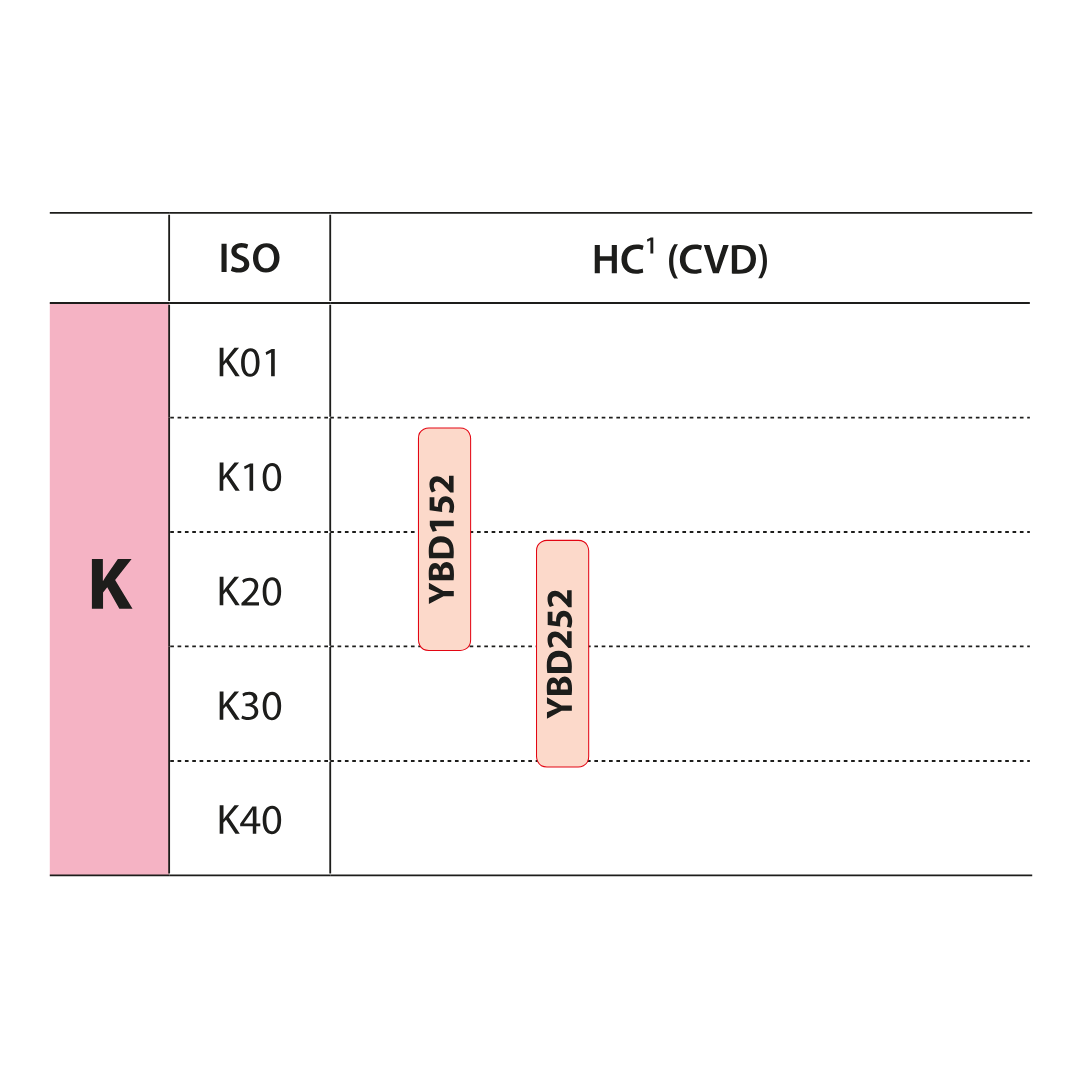

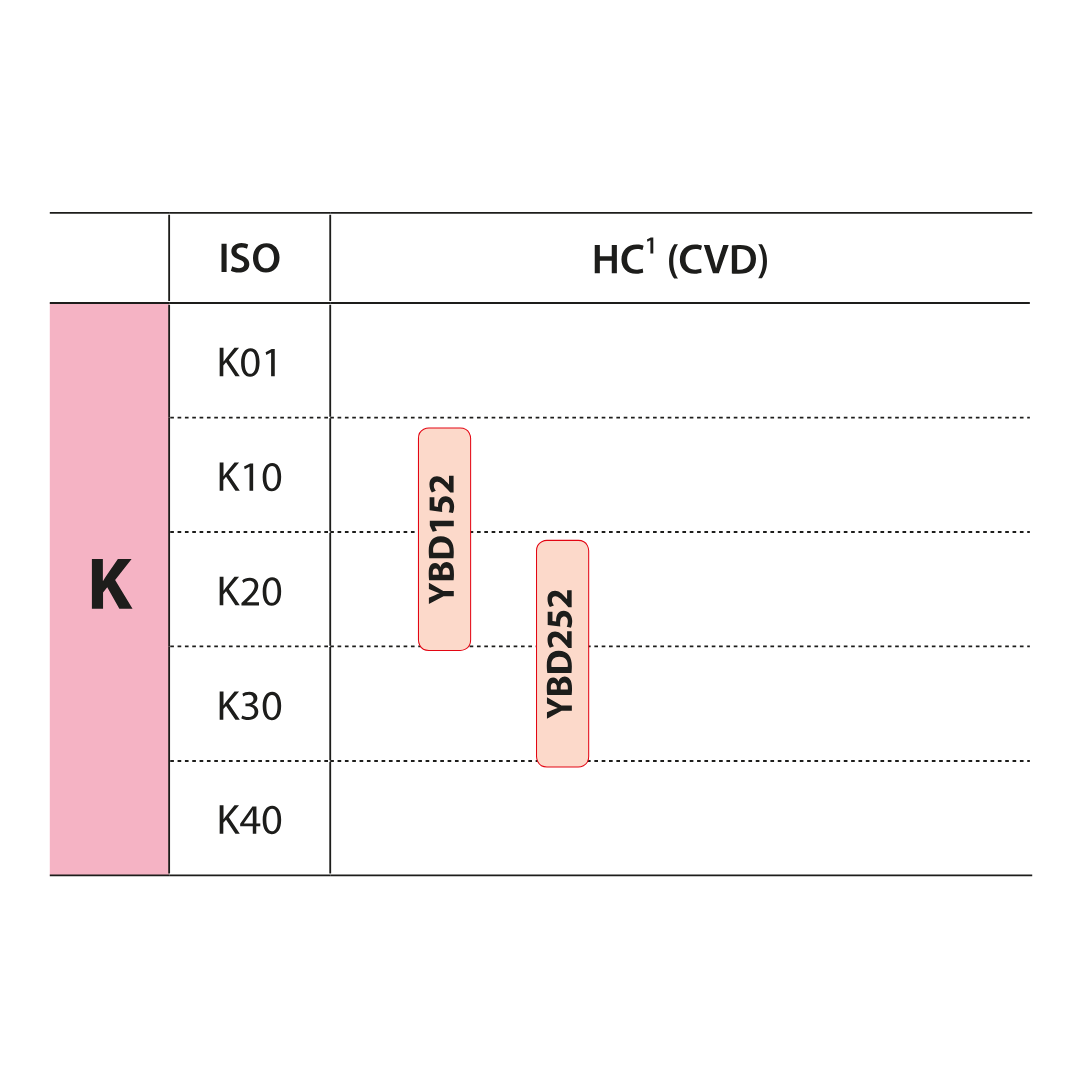

YBD252

ISO: K20 — K35

CVD coated K20–K35 carbide substrate. Optimized for medium to roughing operation of cast iron and Steel. Good wear resistance and toughness at higher cutting speed.

YBD152

ISO: K10 — K25

CVD coated K10–K25 carbide substrate. Optimized for medium to roughing operation of cast iron. Good wear resistance and toughness at higher cutting speed.

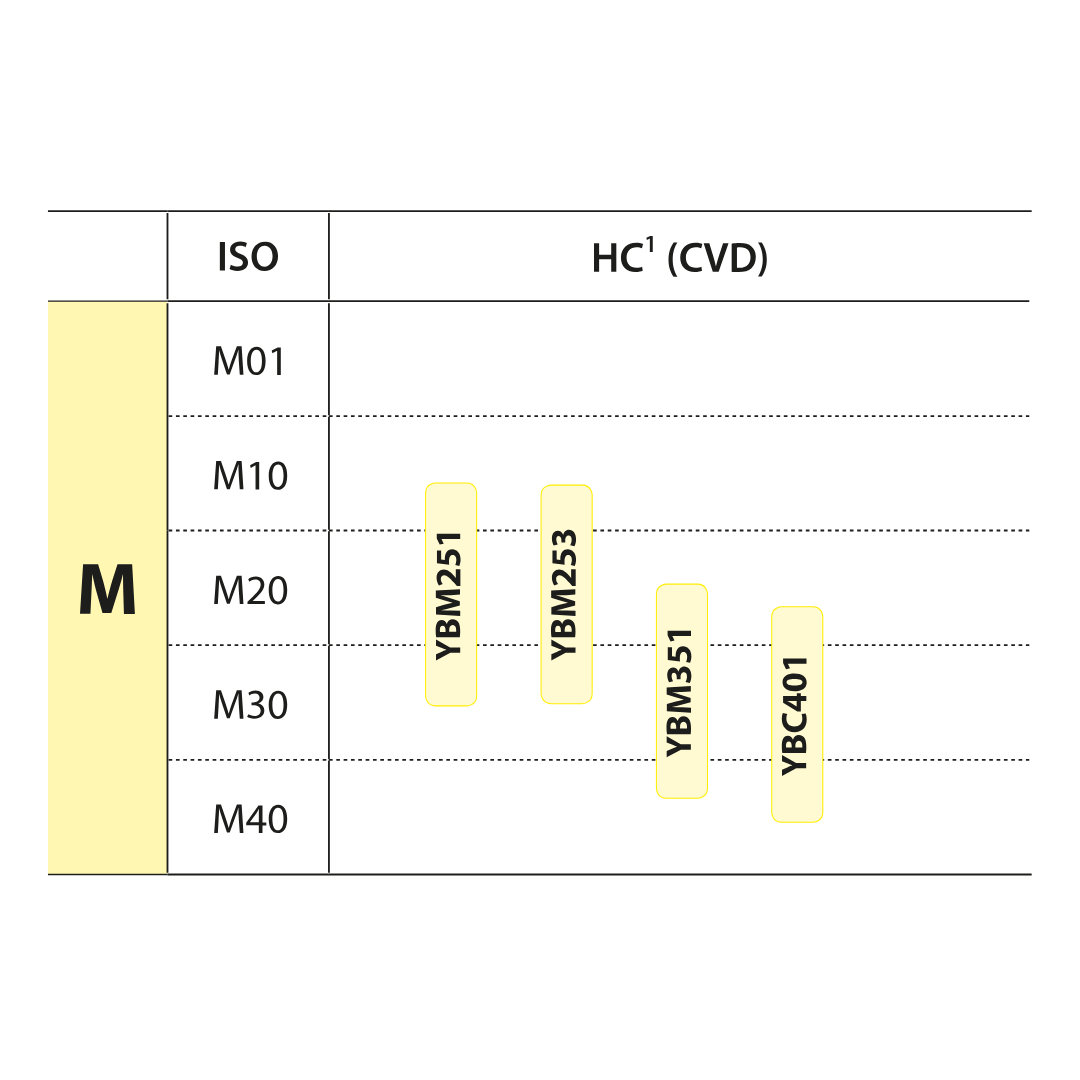

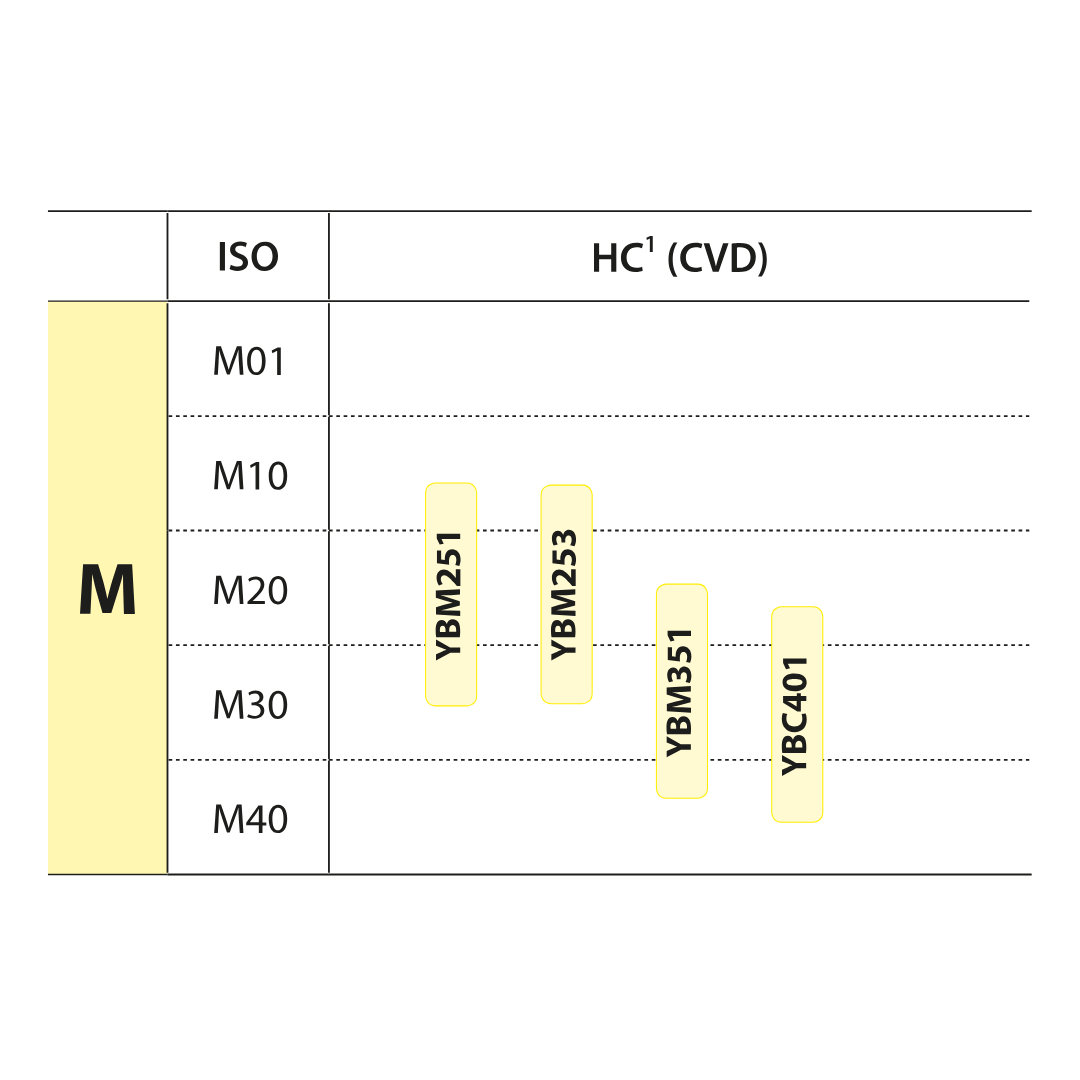

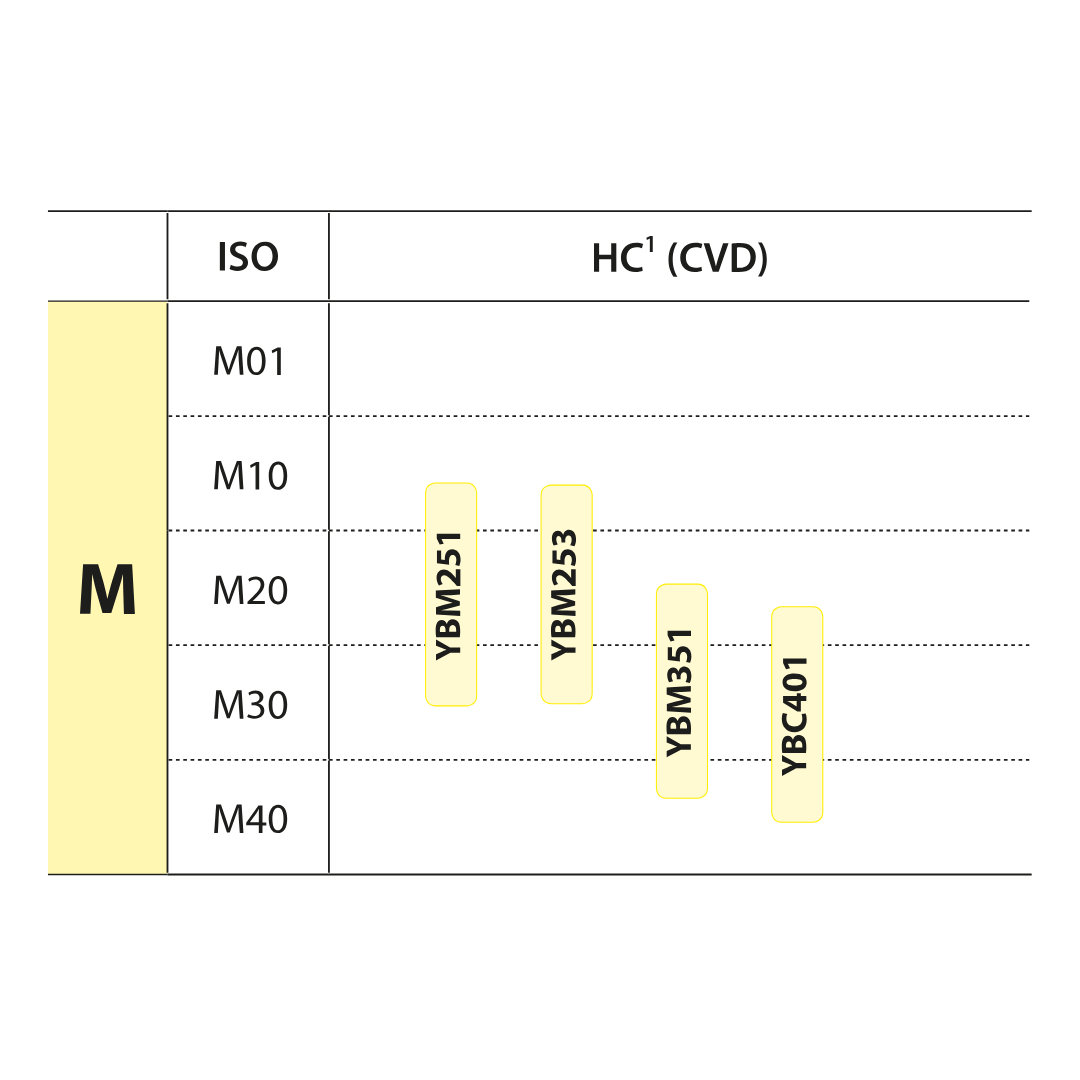

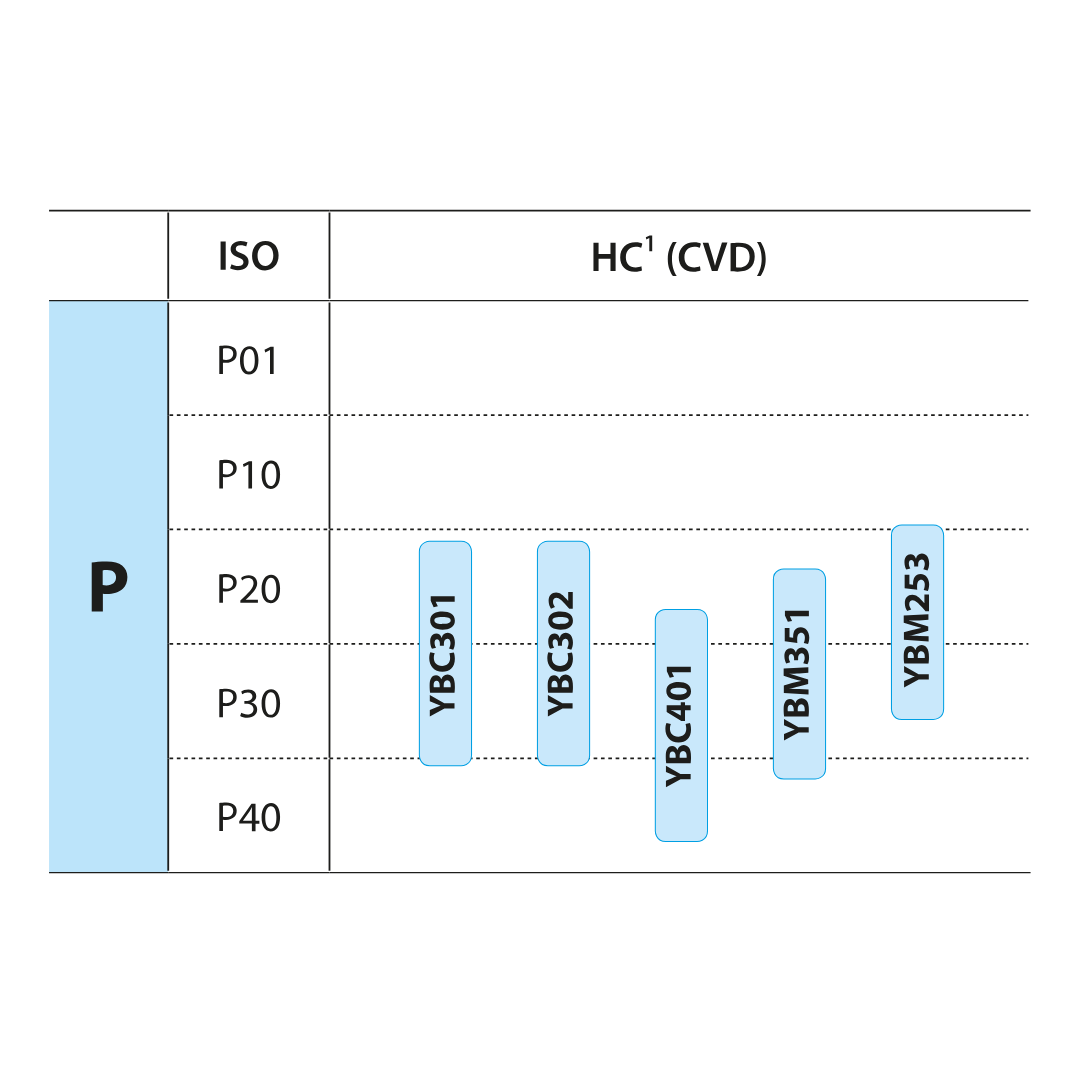

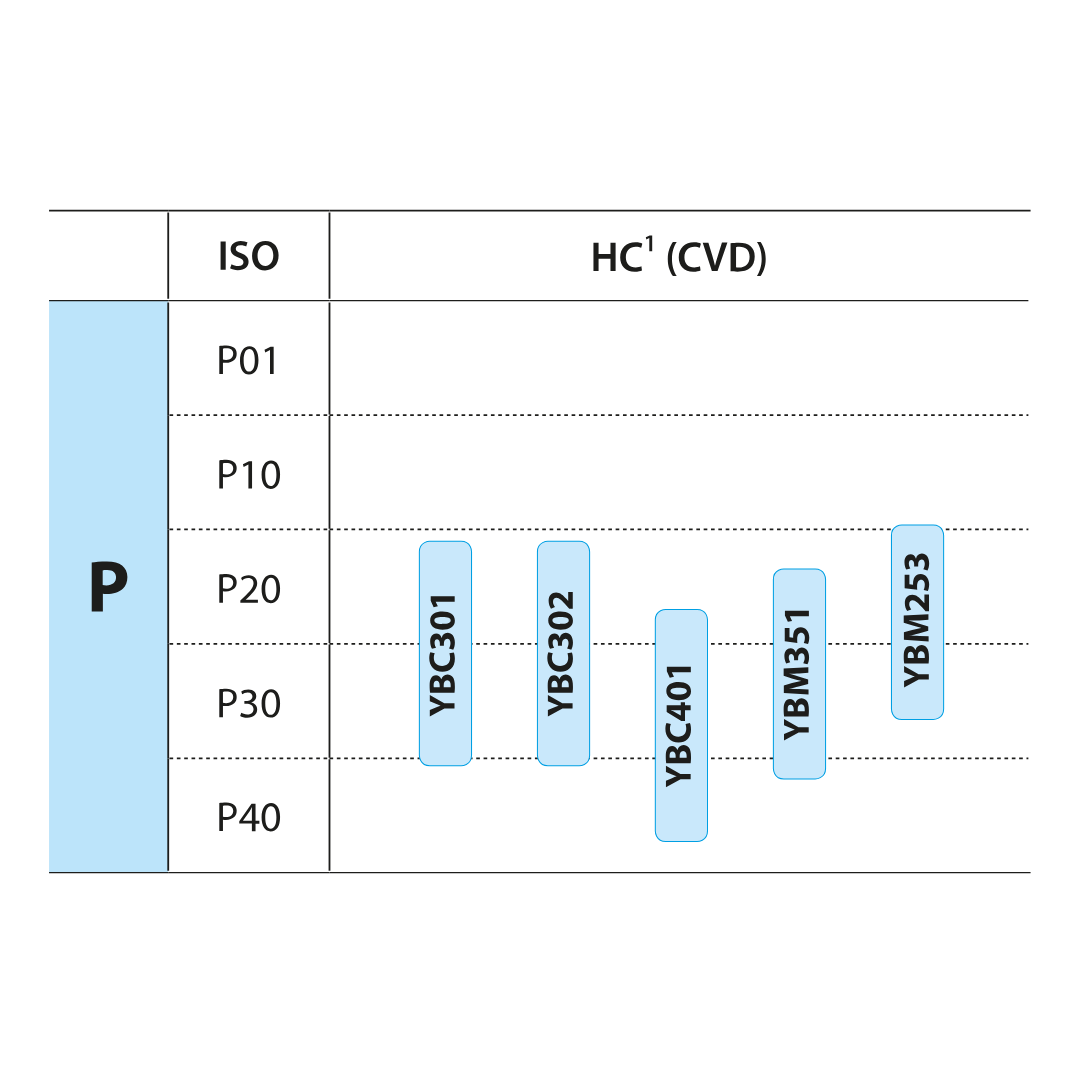

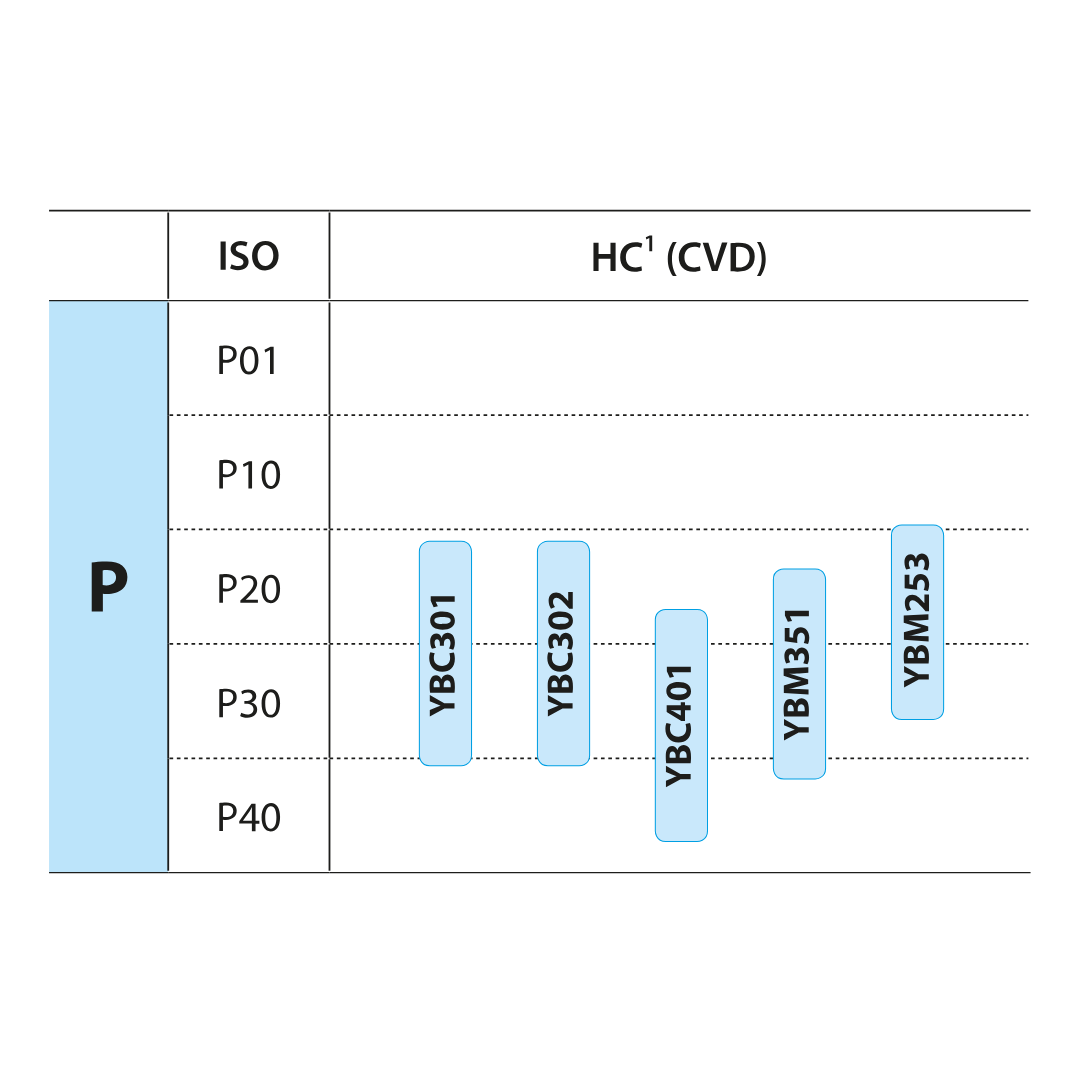

YBM351

ISO: P25 — P40, M20 — M40

CVD coated P25–P40/M25–M40 carbide grade for roughing operation in stainless steel and steel. Good wear resistance and edge stability at normal cutting speed.

YBM251

ISO: P20 — P30, M15 — M35

CVD coated P20–P30/M15–M35 carbide grade for medium to roughing operation in stainless steel and steel with wide application field. Good wear resistance and capability against plastic deformation at normal cutting speed.

YBM253

ISO: M15 — M35

CVD coated M15–M35 carbide grade for medium to roughing operation in stainless steel with wide application field. High wear resistance and capability against plastic deformation at higher cutting speed.

YBC401

ISO: P30 — P50, M30 — M40

CVD coated P20–P30/M15–M35 carbide grade for medium to roughing operation in stainless steel and steel with wide application field. Good wear resistance and capability against plastic deformation at normal cutting speed.

YBC301

ISO: P20 — P35

CVD coated P20–P35 carbide grade for medium operation to roughing of steel at lower cutting speed.

YBC302

ISO: P20 — P35

CVD coated P20–P35 carbide grade for medium operation to roughing of steel at higher cutting speed. Optimal performance of wear resistance and toughness for a wide application field.