Key Features

Applications

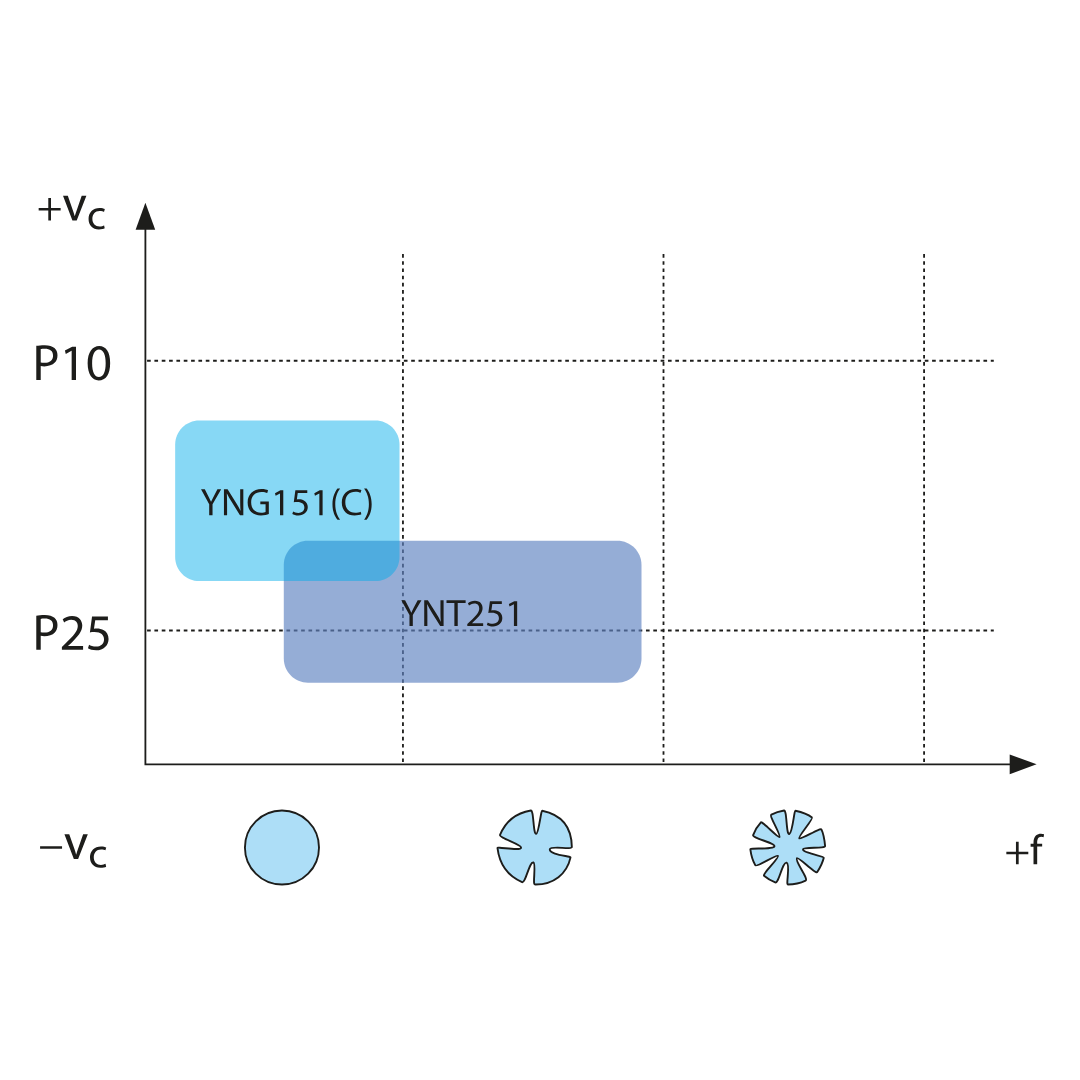

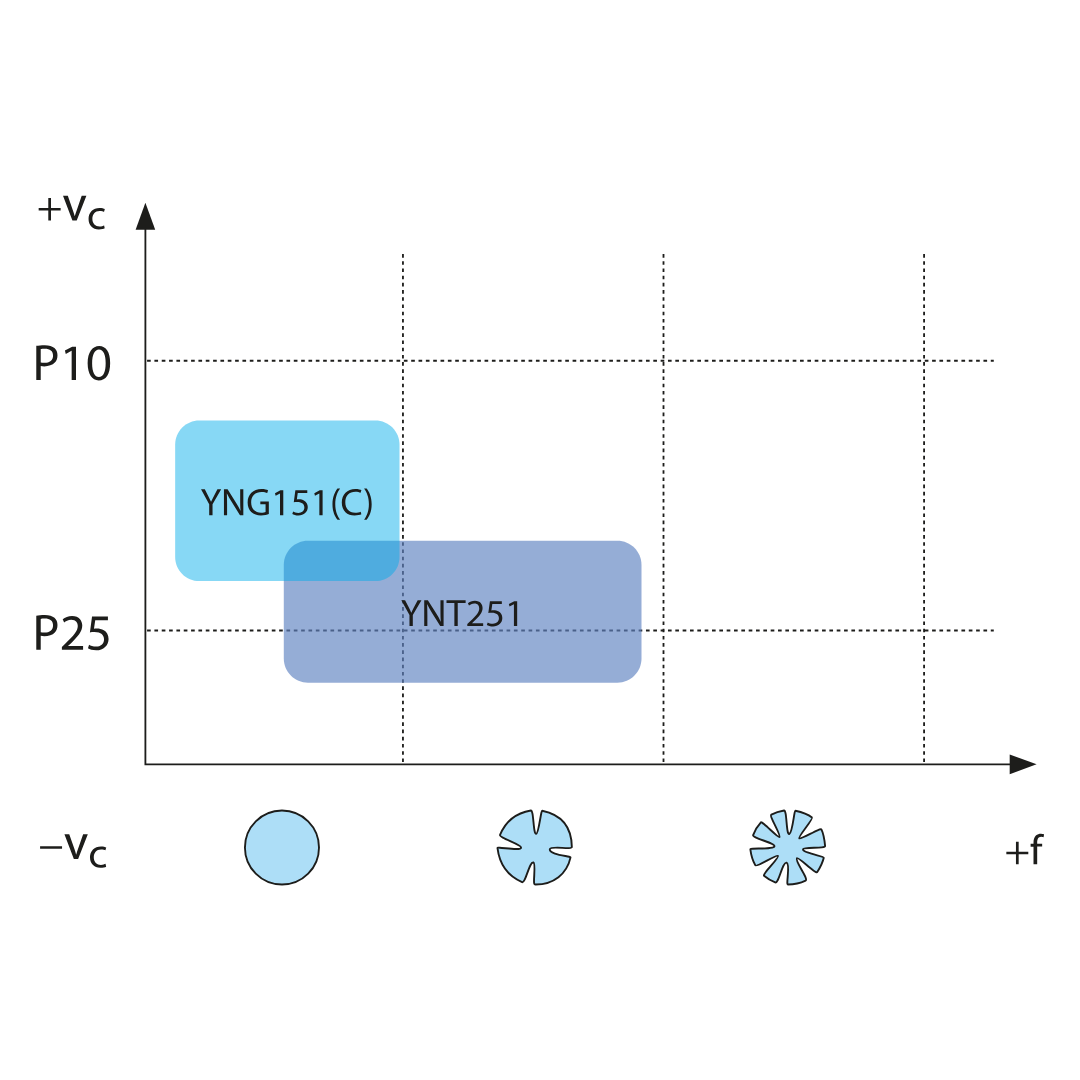

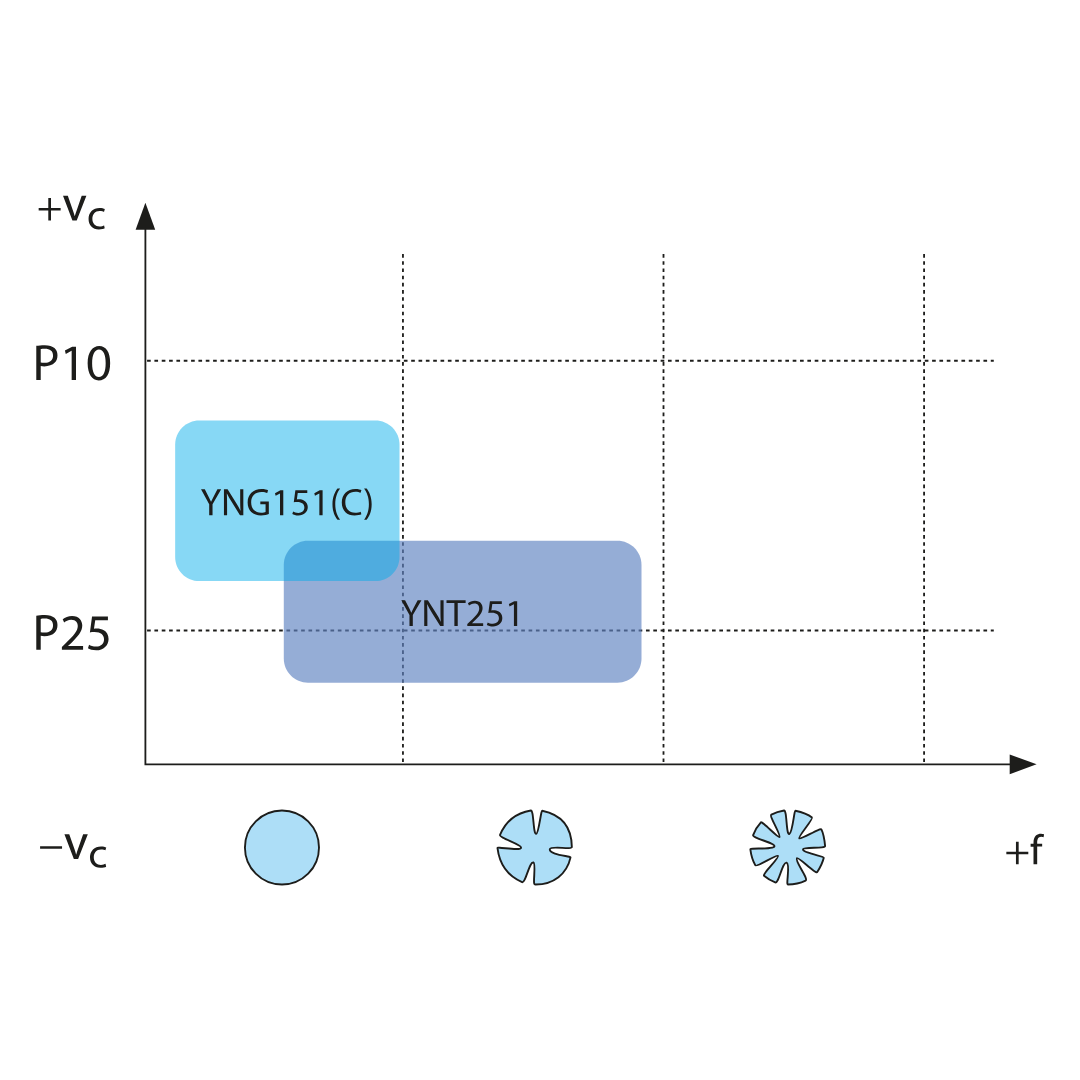

YNG151C

ISO: P05 — P15

PVD coated P05–P15 cermet grade for fine finishing operation of steel and stainless steel. Good wear resistance and capability against plastic deformation for good surface roughness.

YNT251

ISO: P10 — P25

Uncoated P10–P25 cermet grade for fine finishing to medium operation of steel and stainless steel. Good wear resistance and toughness. Suitable also in light interrupted cut.

YNG151

ISO: P05 — P15

Uncoated P05–P15 cermet grade for fine finishing operation of steel and stainless steel. Good resistance against plastic deformation for good surface finishing.