Key Features

Applications

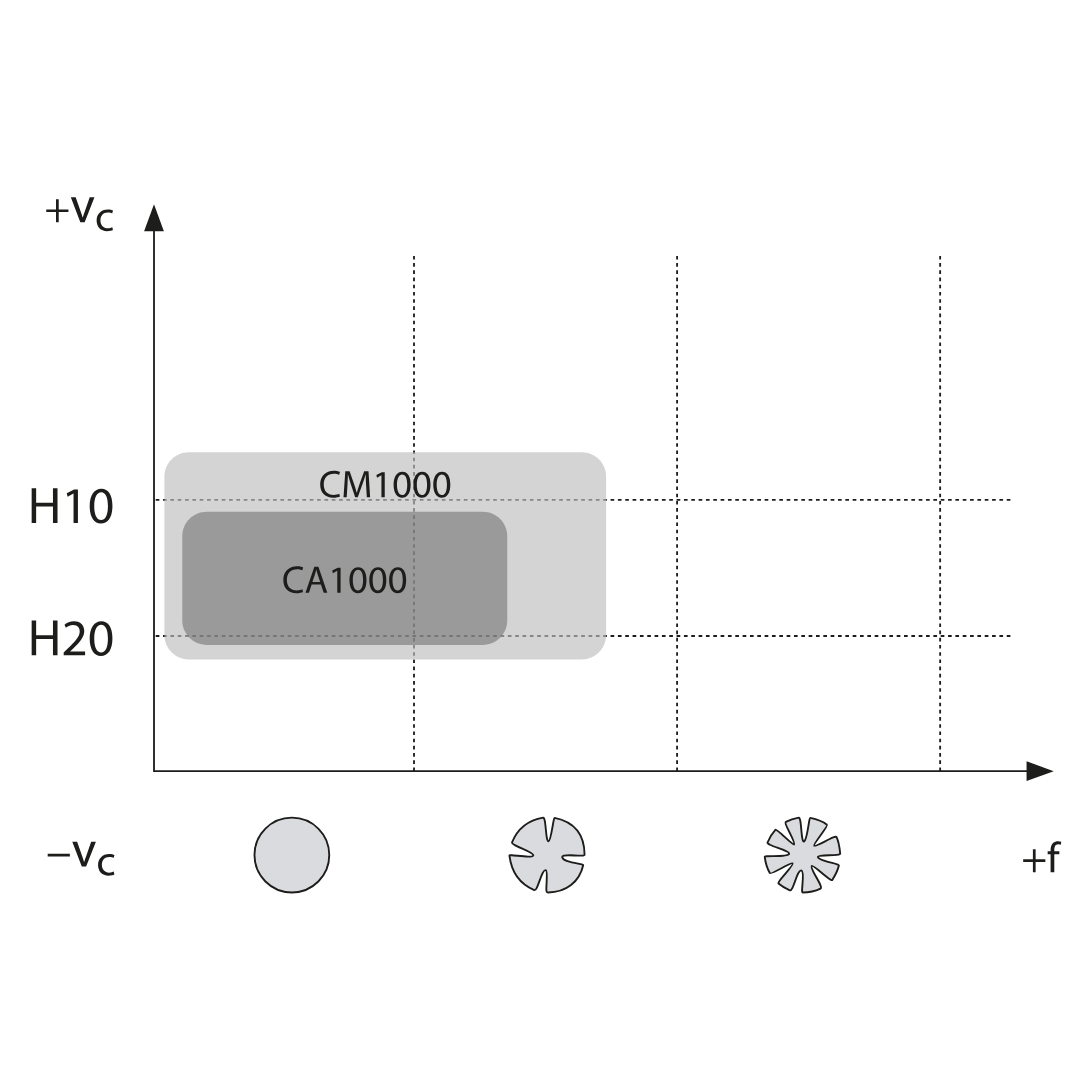

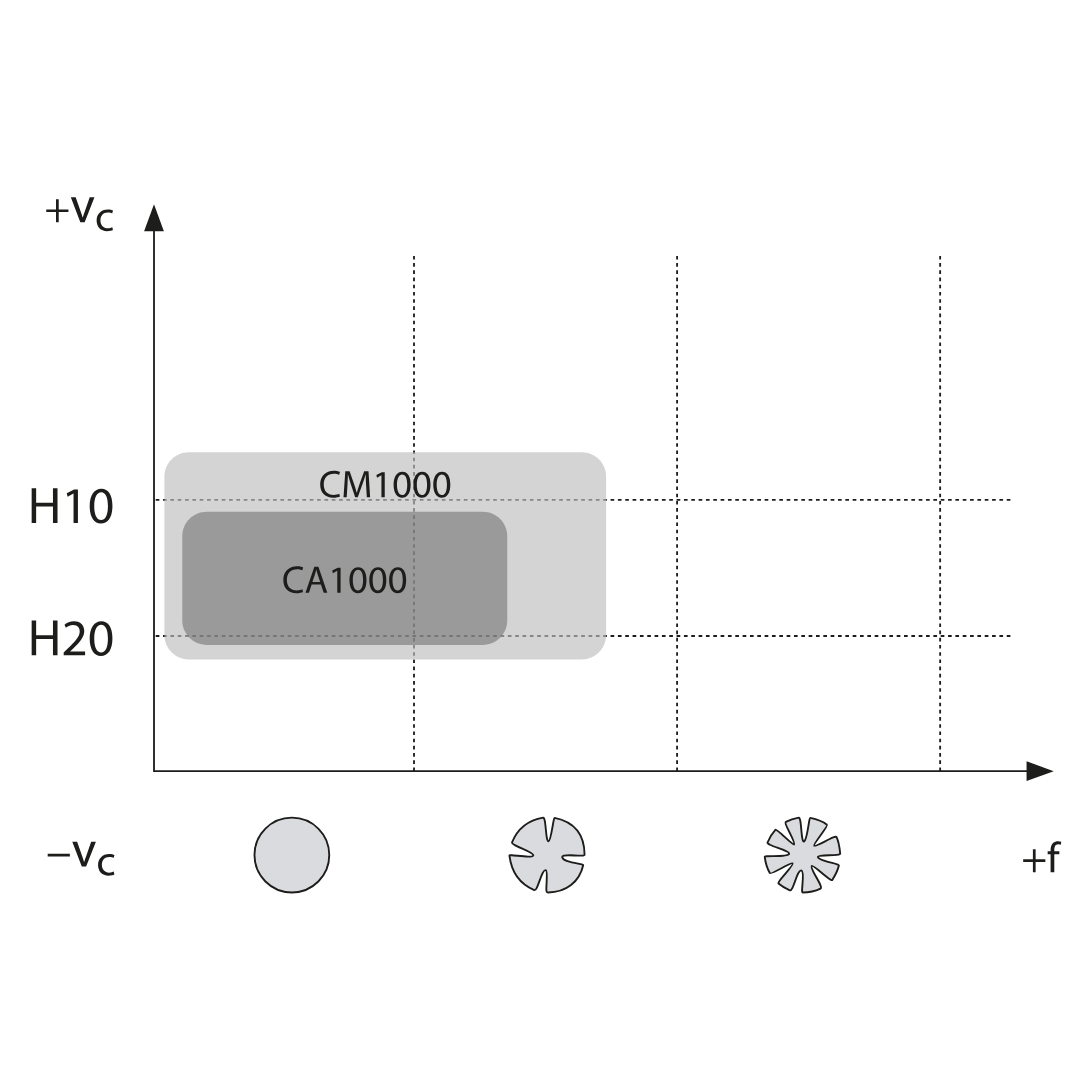

CM1000

ISO: H10 — H25, K10 — K25

Coated H1–H25/K10–K25 mixed ceramic grade for finishing to medium operations in hardened steel, tool steel, HSS material and nodular cast iron. Good wear resistance and toughness.

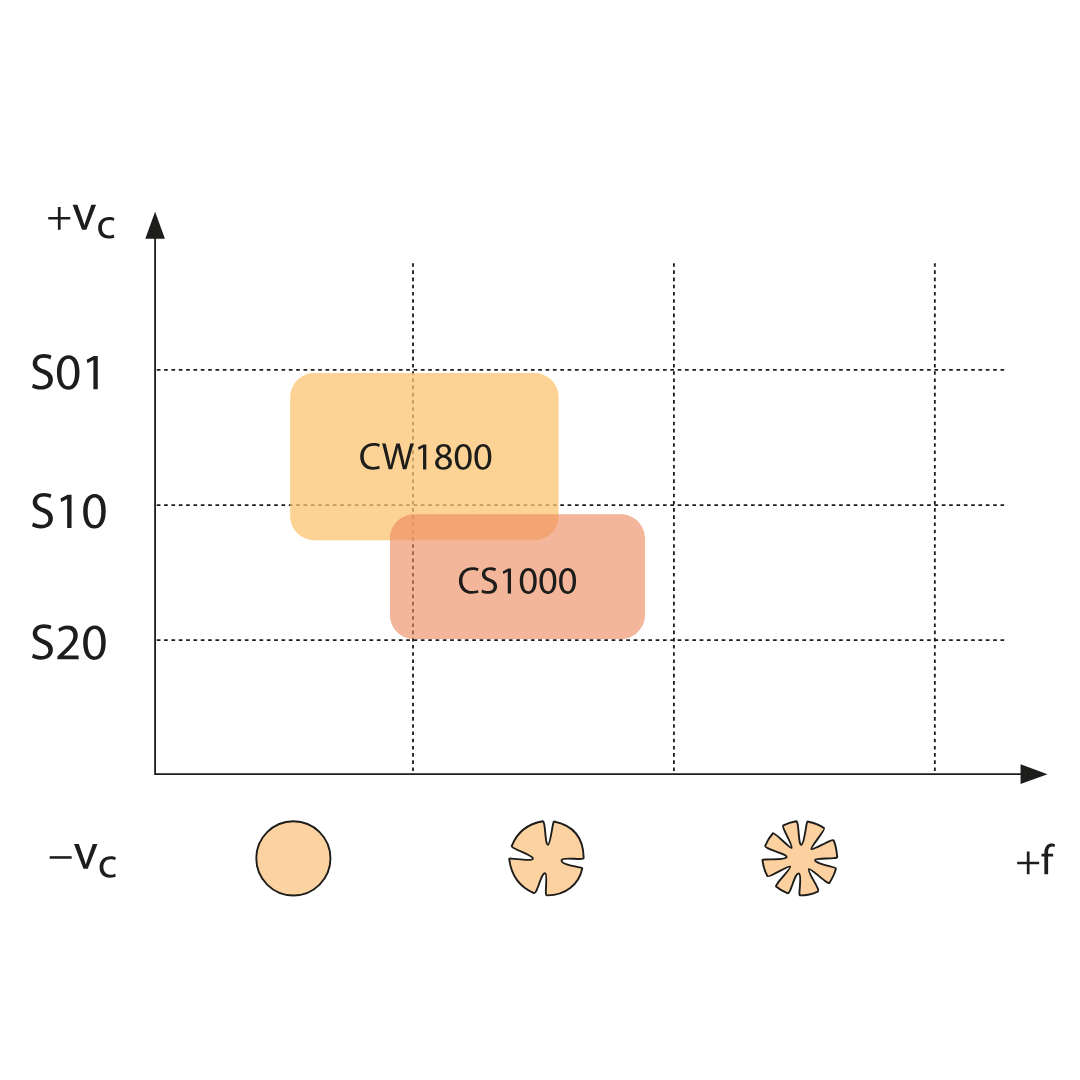

CW1800

ISO: S10 — S25

Uncoated whisker ceramic grade for finishing to rough operations in Ni-base alloy material like Inconel, Nimonic or Hastelloy. Good wear resistance, notch wear resistance and thermal stability.

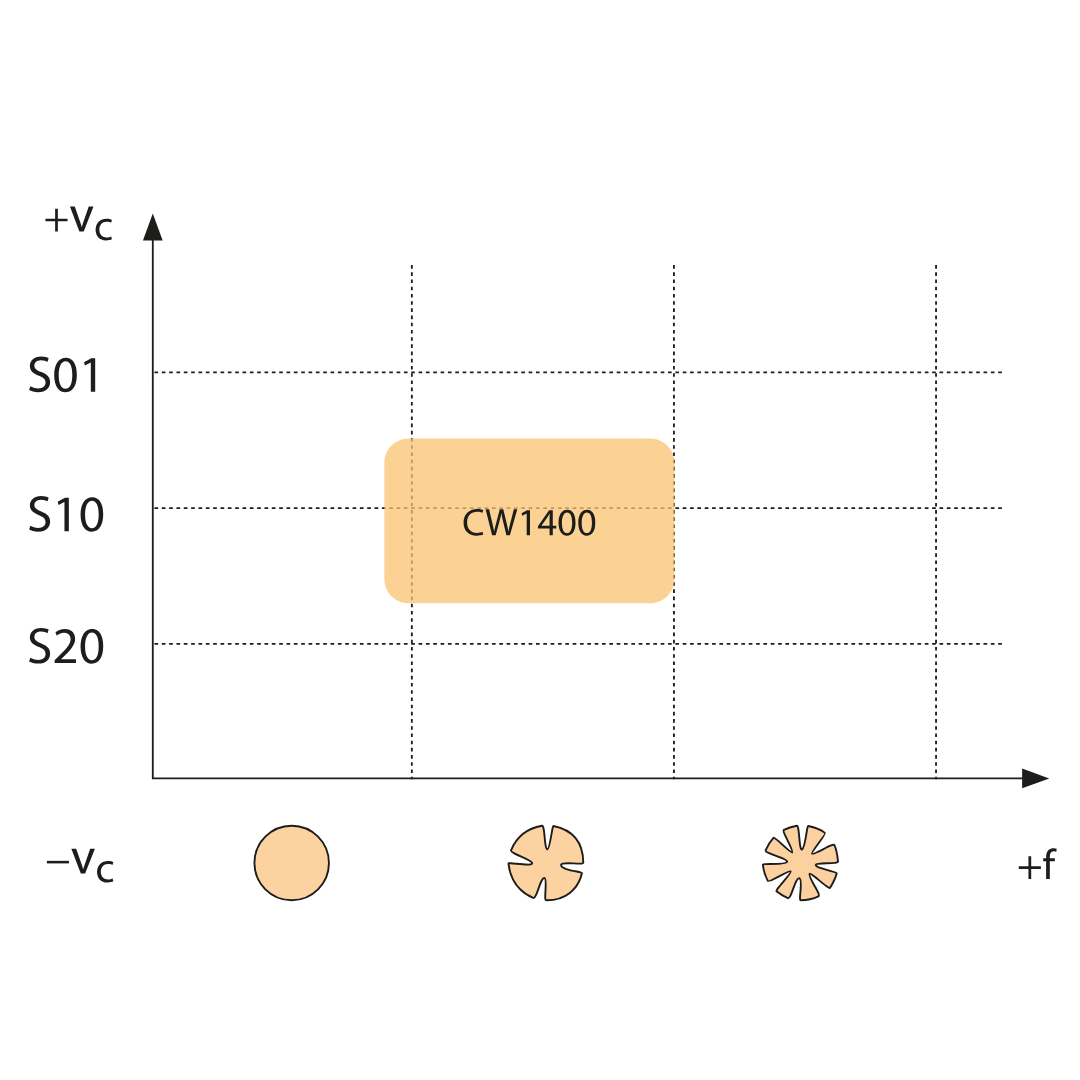

CW1400

ISO: H10 — H20, S10 — S20

Uncoated whisker ceramic grade for medium and low speed cutting in HSS steel, high chrome steel and cobalt-base alloy also with interrupted cut. Good wear resistance, notch wear resistance and thermal stability.

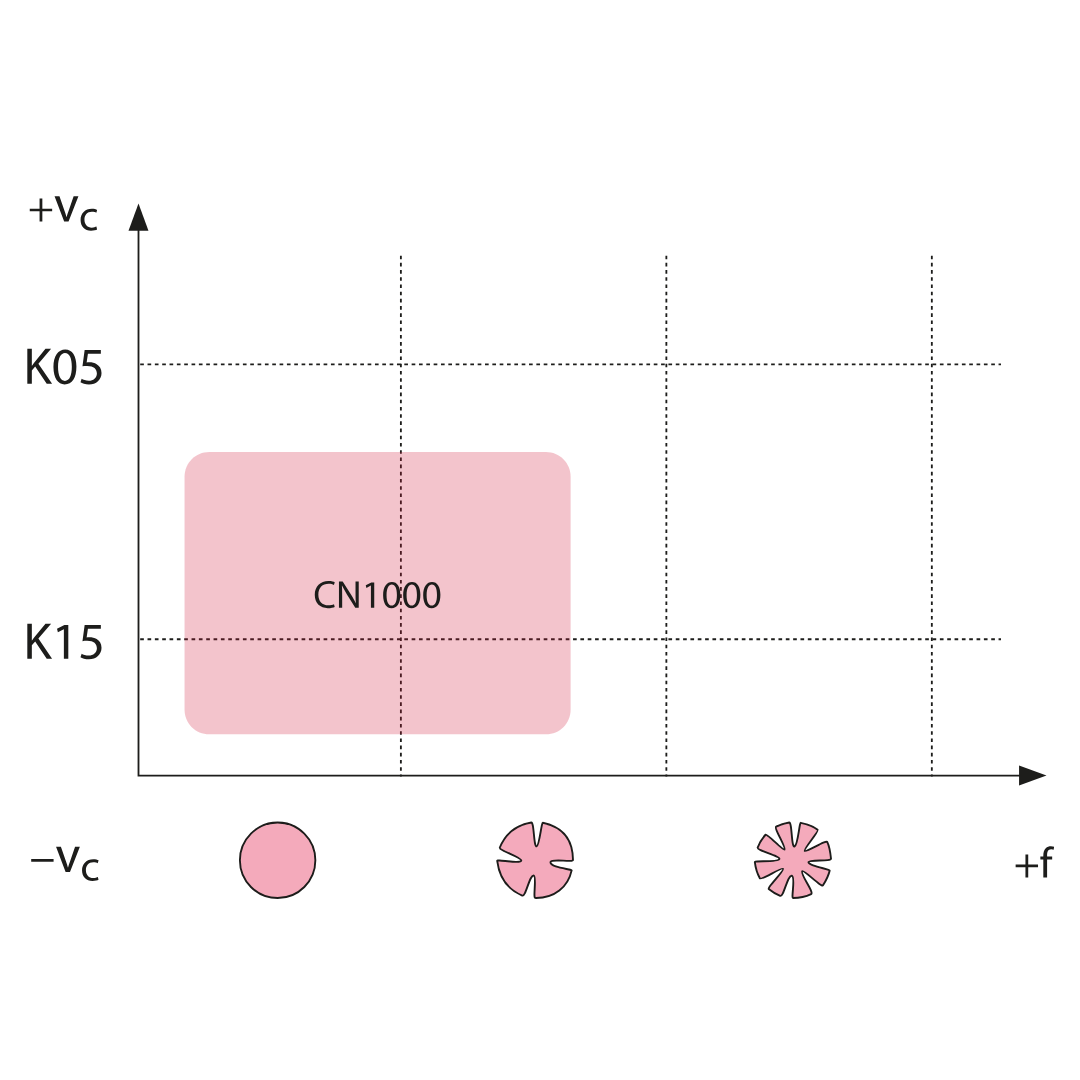

CN1000

ISO: K05 — K15

Uncoated K05-K15 Si3N4 ceramic grade for finishing to medium operation in grey cast iron. Good wear resistance and thermal stability.

CA1000

ISO: K10 — K25, H10 — H25

Uncoated H10–H25/K10–K25 mixed ceramic grade for finishing to medium operation in hardened steel and nodular cast iron. Good wear resistance and toughness.