Key Features

Applications

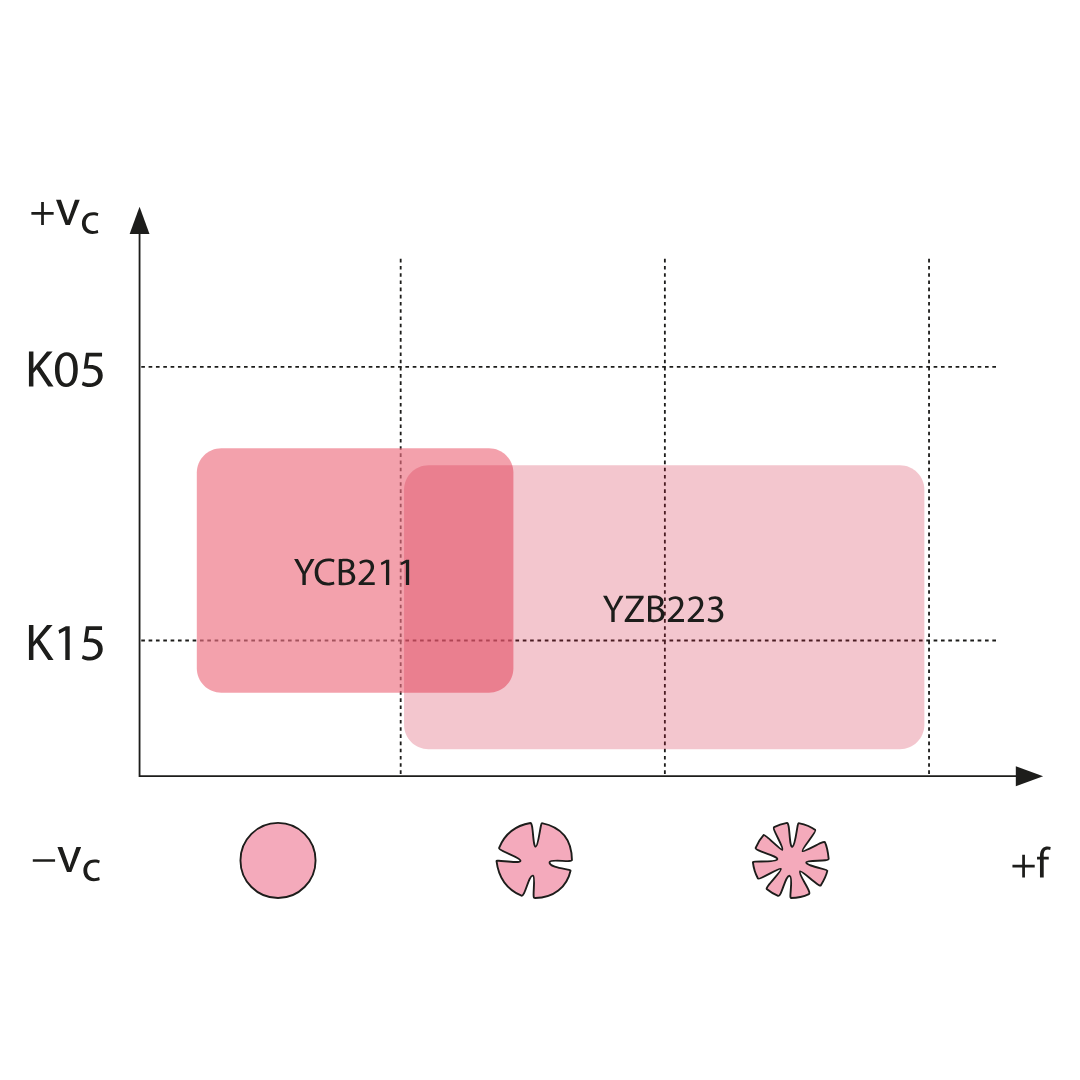

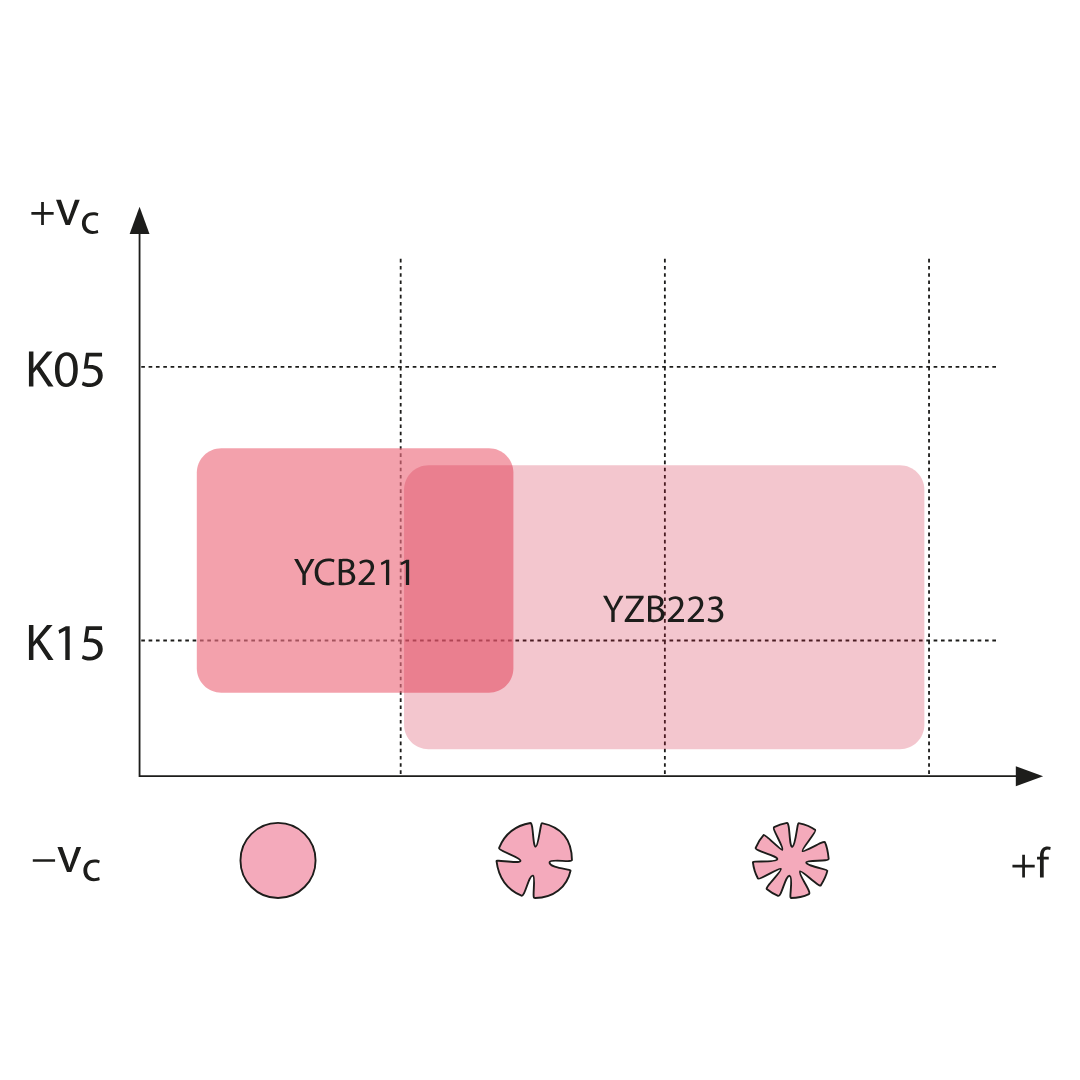

YZB223

ISO: K10 — K25

Uncoated H10–H25/K10–K25 mixed ceramic grade for finishing to medium operation in hardened steel and nodular cast iron. Good wear resistance and toughness.

YCB211

ISO: K10 — K25

Uncoated, brazed K10–K25 CBN grade for fine to medium machining of cast iron. Good wear resistance and thermal conductivity.

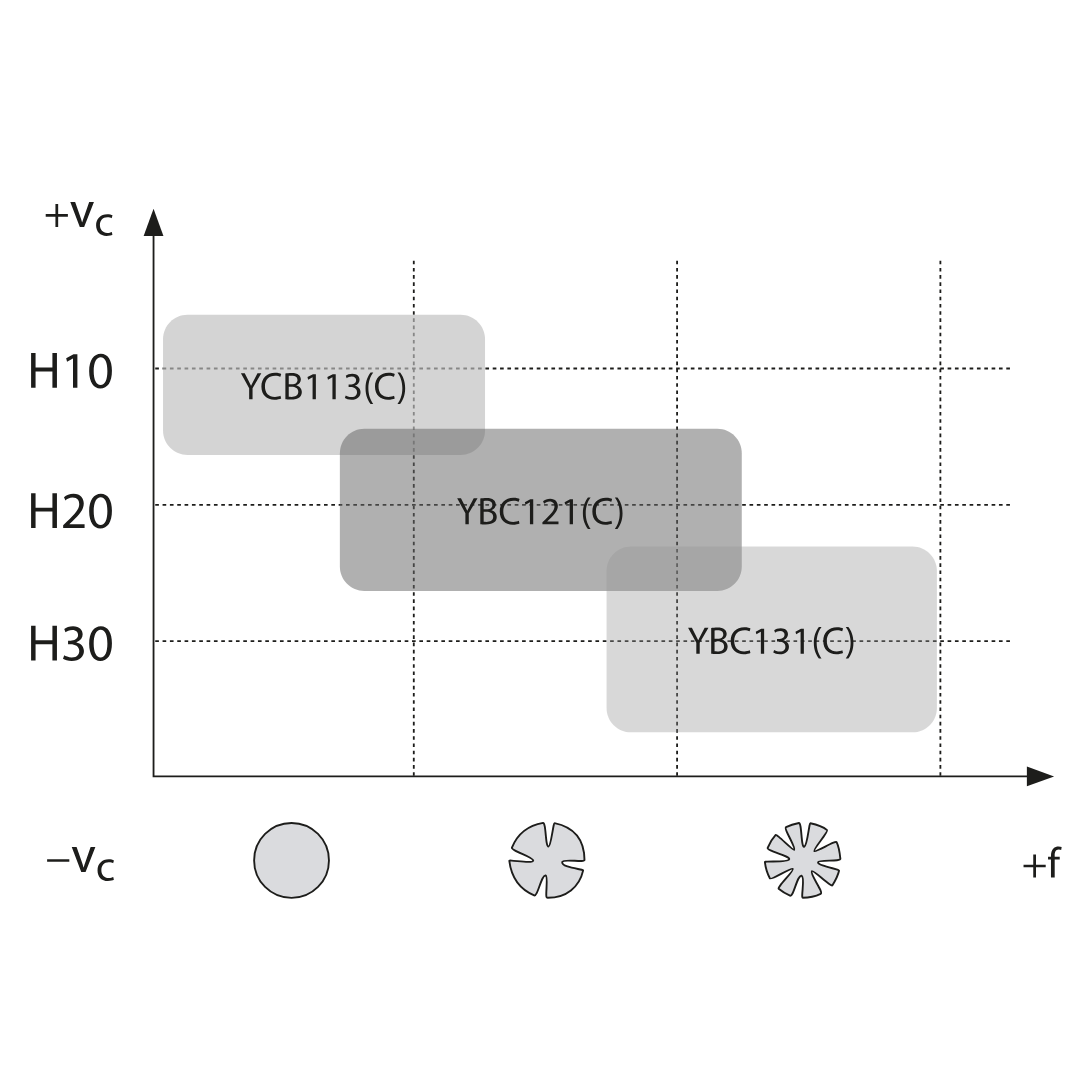

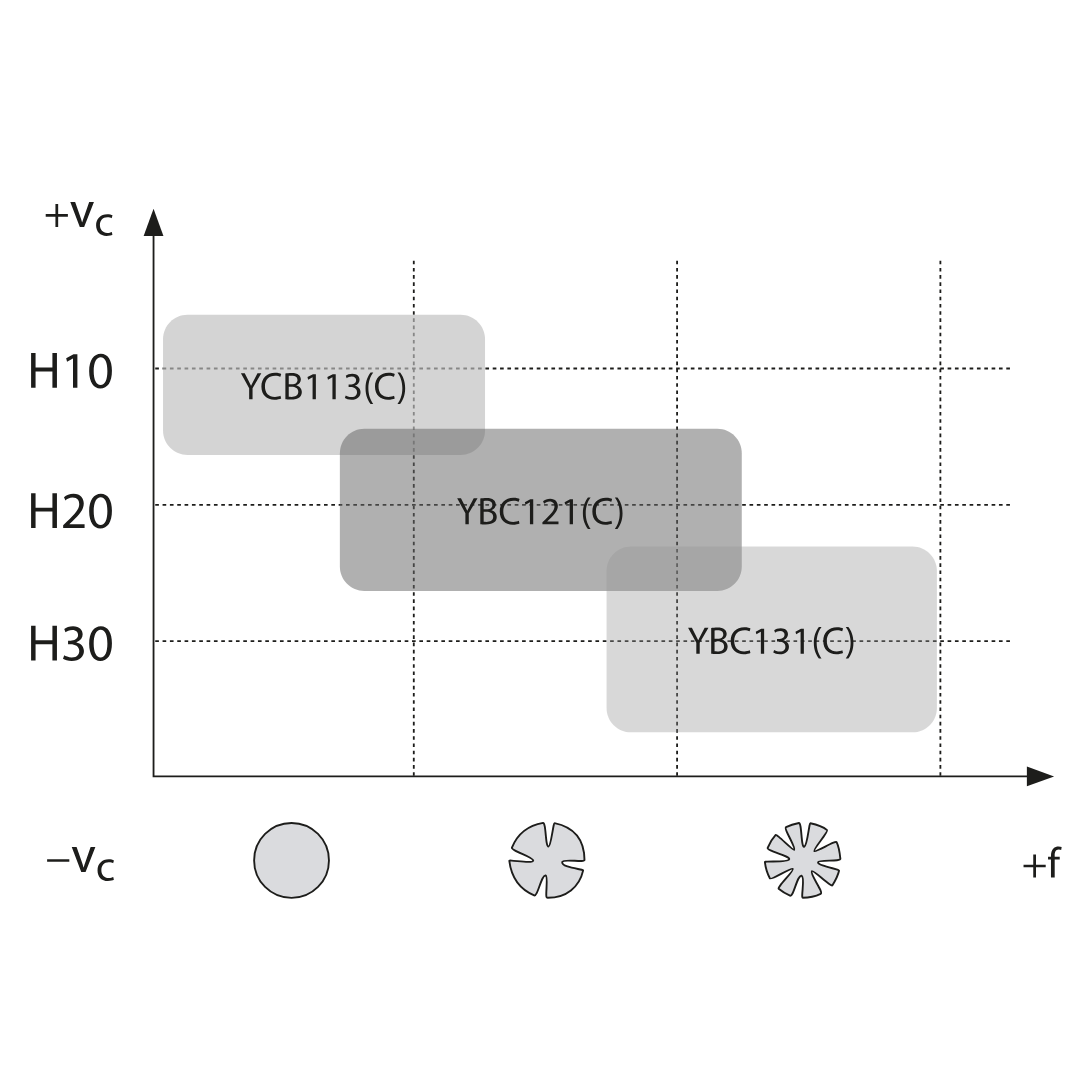

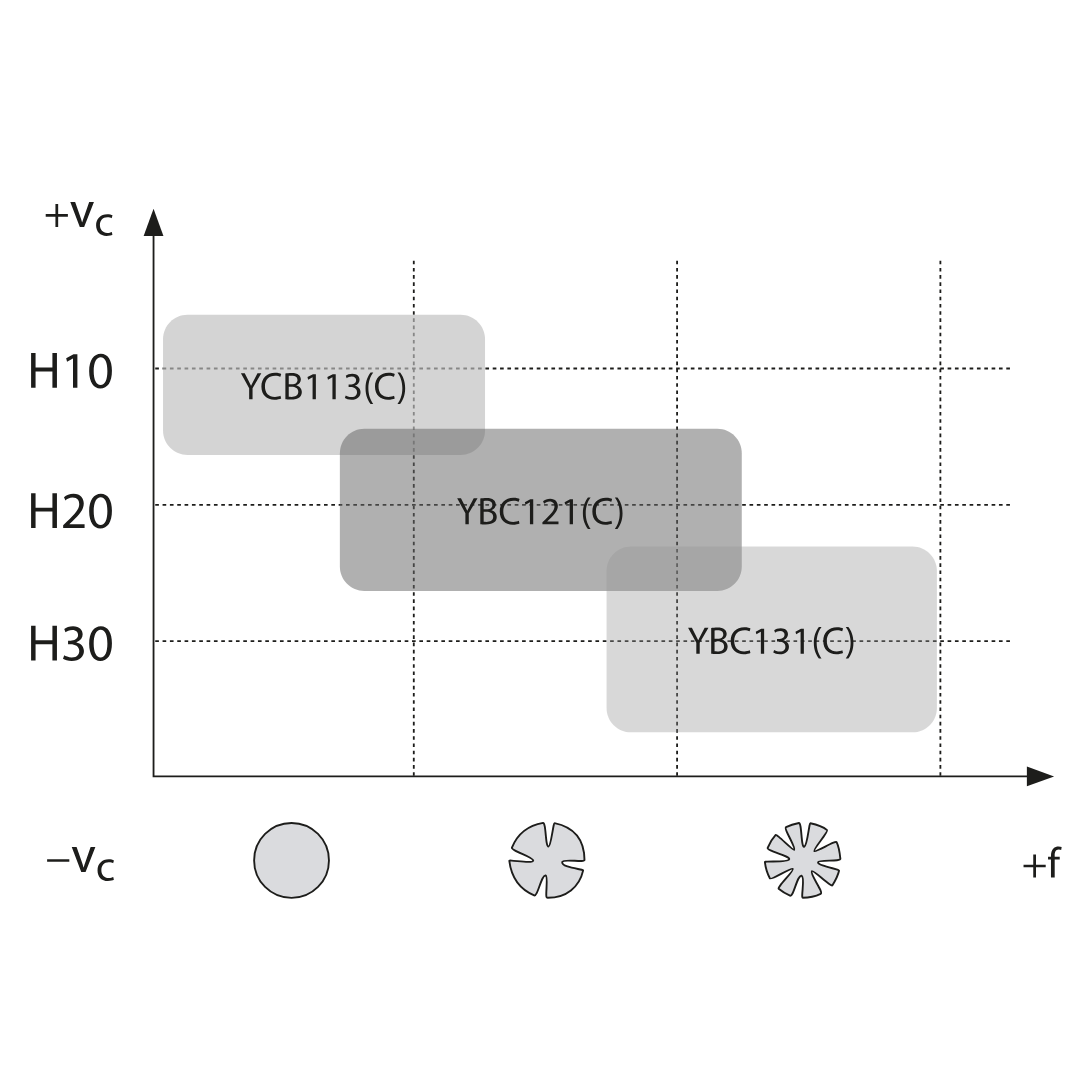

YCB131

ISO: H20 — H35

Uncoated, brazed H20–H35 CBN grade for fine to medium application in hardened steel with interrupted cut. Good wear resistance and optimized toughness for safe process.

YBC121

ISO: H10 — H25

Uncoated, brazed H10–H25 CBN grade for fine to medium application in hardened steel from continuous to light interrupted cut. Good wear resistance and toughness for universal use.

YBC113

ISO: H01 — H10

Uncoated, brazed H01–H10 CBN grade for fine finishing operation in hardened steel with continuous cut. High wear resistance and productivity at higher cutting speed.